Fertilizer Production from Carbon Ammonia

- Production Capacity: 10,000 to 200,000t Annually Organic NPK Fertilizer Production

- Turnkey Project Solutions:Provided

- Customized Services:Provided

- Installation:Provided

- Main Equipment:Grinder, Blender, Conveyor, Granulator, Dryer and Cooler, Coater, Packer, etc.

Get Price Now!

Description

Ammonium bicarbonate is a nitrogen fertilizer with low nitrogen content (only 17%), poor stability, easy decomposition and caking. Due to these shortcomings of ammonium bicarbonate, many difficulties are brought about in storage, transportation and use.

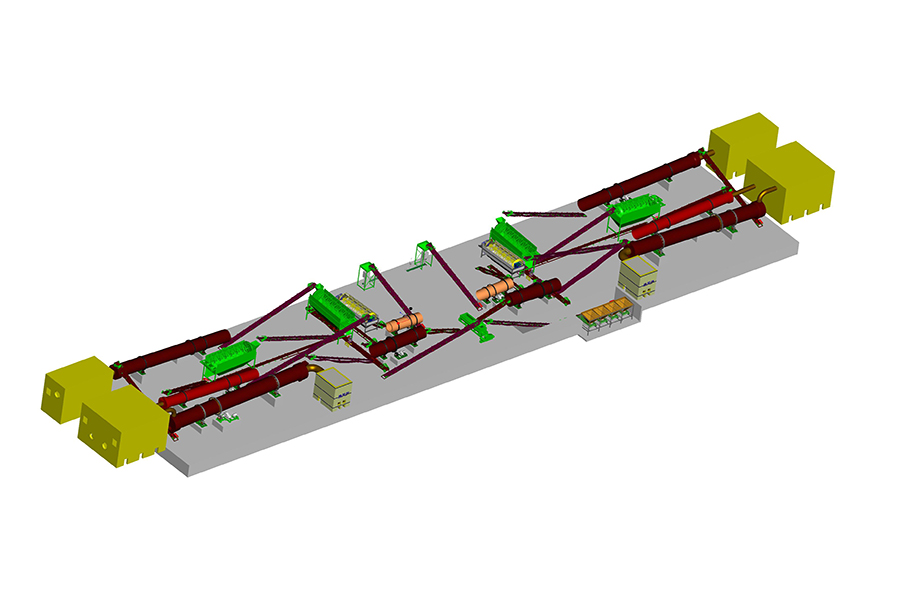

NPK Production Factory from Carbon Ammonia for Sale

Therefore, in view of the shortcomings of ammonium bicarbonate, the research on the use of ammonium bicarbonate to produce compound fertilizers has become an important topic in the field of chemical fertilizers of our company recently. In the production of compound fertilizers with ammonium bicarbonate, the key problem is to solve its decomposition loss. There are many factors that promote the decomposition and volatilization of ammonium bicarbonate, of which water content is one of the main factors, so reducing the free water content in ammonium bicarbonate is a powerful measure to improve its stability.

Experiments have proved that after the dry calcium phosphate is mixed with ammonium bicarbonate, the available phosphorus will not be degraded, and most of the water-soluble phosphorus will be converted into citrate-soluble phosphorus in a short time; the stability of the mixture is mainly related to the quality of the water and ammonium bicarbonate itself moisture, particle size) and mixing ratio. As long as these indicators are optimally selected, compound fertilizer products with better physical properties and effective nutrient stability than ammonium bicarbonate can be obtained.

NPK Production process with carbon ammonia

Ammonium bicarbonate and general calcium process

(1) Raw material specifications

- Ammonium bicarbonate: containing N≥17%;H20≤3.0%;Particle size 20~40 mesh;

- Calcium general: After pretreatment, it contains available phosphorus (P2O5) ≥14.5%;H20≤1.5%;Particle size 30~60 mesh;

- Potassium chloride: containing K2O≥59%;particle size 20 mesh;

- Other raw materials:H20≤1.5%;particle size 20 mesh;

(2) Process flow

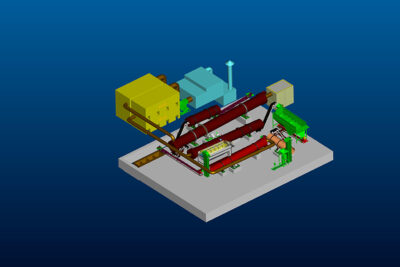

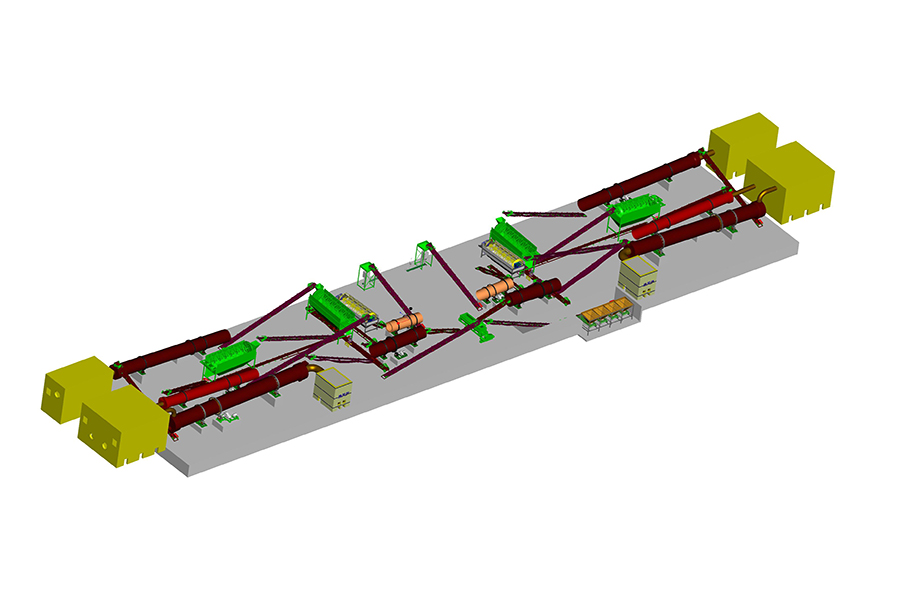

The process flow of producing ternary compound fertilizer with common calcium, ammonium bicarbonate, potassium chloride, etc. as raw materials is shown in Figure 2-19.

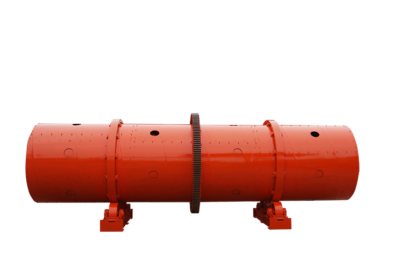

(3) Common calcium drying

Common calcium drying is the same as ordinary urea production compound fertilizer process. Generally, a drum dryer is used for drying, and a co-current drying method is adopted, that is, high temperature gas and materials flow in the same direction in the drum to prevent the material is locally overheated. In order to keep the phosphorus in common calcium from degrading during the drying process, attention must be paid to controlling the temperature. Usually, the temperature can be changed by adjusting the fan induced air volume or the feeding volume. Generally, the inlet gas temperature should be controlled to be ≤52°C, the outlet gas temperature should be ≤85°C, and the outlet material temperature should be ≤60°C. The structure diagram of the dryer is shown in Figure 2-20.

(4) Mixed

Weigh all kinds of fertilizers according to the intended formula and put them in the mixer blender to mix them evenly. Mixing is a particularly important process in the production of ammonium bicarbonate compound fertilizer, which not only makes the nutrients evenly mixed, but also must ensure that the material can quickly complete its chemical reaction. Mixing can choose JB-300 horizontal two-way screw mixer as mixing equipment. In order to remove the heat generated during the reaction in time and keep the temperature of the reaction material, the mixing equipment is cooled with water with a jacket.

(5) Aged

In addition to mechanical mixing, the materials are also accompanied by chemical reactions. Not only should the mixed materials be uniform and fully contacted, but also the time required for them to react completely. Therefore, after the mixing is complete, the material should be sent to the screw conveyor to age while moving. In order to remove the residual heat of the reaction in time, a water-cooling jacket must be installed in the screw conveyor, and the water is cooled during operation to keep the material at a low temperature. The use of screw conveyor for aging has the advantages of small dust, stable operation, and continuous renewal of the surface of the material, and the aging effect is good.

(6) Granulation

Because ammonium bicarbonate is relatively easy to decompose, the traditional drum granulation process and disc granulation process cannot be used. The ideal and currently used more successful process is the extrusion granulation process. In order to control the temperature in the process, lubricants can be added during the granulation process, and the granulator is extruded on the rollers by cooling with water.

The material is continuously fed into the working room of the counter-roll extrusion granulator, and passes through the pressing roller and the granulating die (which can be

(replacement) are extruded into cylindrical strips, the material is extruded from a small hole with a certain diameter, and then cut and discharged by an adjustable cutter according to the required length, that is, the finished product. The average compressive strength of the particles is ≥10N, exceeding the average compressive strength specified by some professional standards (ZBG 21002- -87) ≥8N, the qualified rate of finished products is ≥90%, and basically no material is returned. The structure, working principle and operating conditions of the granulator are the same as those described above.

(7) Three waste treatment

The exhaust gas discharged from dryers, pulverizers, mixers, screening machines, etc., mainly contains NH3, CO2, dust, etc., which is collected by fans and cyclones, and then washed by absorption towers or absorption pools. into the atmosphere.

(8) Economic and social benefits

The production cost of using ammonium bicarbonate to produce 12-5-8 granular compound fertilizer is: the total cost is 497 yuan/t. According to the market price of 600 yuan / t, the profit tax per ton is 103 yuan. Among them, the raw material cost is 398 yuan/t, and the secondary processing fee accounts for 24.9% of the raw material cost. The secondary processing fee is slightly lower than other processes, indicating that the process is economically reasonable.

In the production of compound fertilizer with ammonium bicarbonate, the loss is less than 2.0%, the loss of common calcium (removal of water) is less than 1.5%, and the loss of other raw materials is less than 0.5%. The pure yield of the product in the production process (that is, the number of finished products packaged in storage divided by the amount of raw materials added) > 98%. The total nutrients of nitrogen (N) + phosphorus (P2O3) + potassium (K20) in the product are ≥25%, and all indicators can meet or exceed the requirements of ministerial standards. The appearance is gray-brown cylindrical strips, without visible mechanical impurities, and no knots. Block, moisture absorption is not obvious.

Production process of ammonium bicarbonate and monoammonium phosphate compound fertilizer

The main raw materials of compound fertilizer produced by this process are: ammonium bicarbonate, monoammonium phosphate, potassium chloride and conditioner. The process flow is basically the same as the process flow of ordinary calcium production, and the process flow is shown in Figure 2-21.

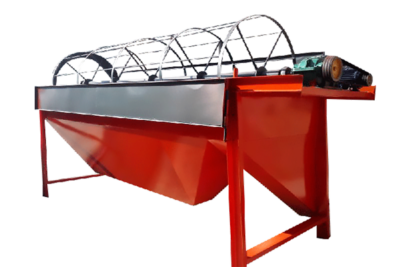

Weigh the ammonium bicarbonate, powdered monoammonium phosphate, potassium chloride, conditioner, and binder according to the formula, add them to the mixer, and mix them. The granular compound fertilizer from the granulator is aged and conveyed by the belt conveyor, and then enters the fertiliser screening equipment. After screening, the qualified particles are sent to the storage silo for packaging, and the unqualified powder is returned to the fertilizer mixer for re-mixing and production. The dust and a small amount of ammonia generated in the production process are absorbed by the fan and collected by the cyclone dust collector, and then processed and emptied by the absorption washing tower or washing pool. The dust recovered by the cyclone is returned to the mixer for reuse.

The production of ternary compound fertilizer with ammonium bicarbonate is the same as the production of compound fertilizer from other nitrogen sources. The proportion of nitrogen, phosphorus and potassium in the product can be formulated according to the needs of agricultural production. It can often be formulated into 12-6-7, 10-10-10 Wait. The water solubility of P2Os in the product is ≥40%, and the effective rate of P2Os is ≥97% H20<3.5%. The diameter of cylindrical products is 3.2 ~ 4mm, the aspect ratio is 1.5 ~ 2.0, and the particle strength is ≥ 8N/grain. The chemical drying and the encapsulation of magnesium ammonium phosphate make the stability of ammonium bicarbonate compound fertilizer much higher than that of the raw material ammonium bicarbonate. The product is dry, does not agglomerate, and has a slight ammonia smell. After 3 months of storage, the quality of the product is still in line with the above indicators.

The production of compound fertilizers with ammonium bicarbonate has successful examples in many units in my country, but the basic processes are the above two. The difference is that the dehydrating agent added to increase the stability of ammonium bicarbonate is different, and the name is also different. different, such as conditioners, additives, modifiers, etc. But roughly the following materials: dolomite, high temperature salt (MgCl2), magnesite, gypsum, etc. After these materials are added, they will form magnesium ammonium phosphate hexahydrate or calcium sulfate dihydrate with ammonium bicarbonate, which can absorb the moisture in ammonium bicarbonate and increase its stability.

Except for some special treatments mentioned above, the production of compound fertilizer with ammonium bicarbonate is the same as the above-mentioned ordinary compound fertilizer production process.