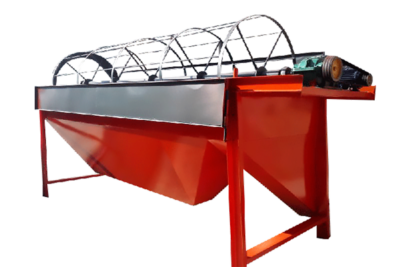

Organic Compound Fertilizer Pan Granulator

- Output (kg/h): 0.5-6t/h

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Core Components: Engine

- Brand Name: Gate

- Voltage: 220/380v

- Dimension(L*W*H): 1800*1200*1600mm

- Weight (KG): 524

- Power (kW): 2.2

- Applicable Industries: Farms, Chemical Factory

- Rotate Speed: 21r/min

Get Price Now!

Description

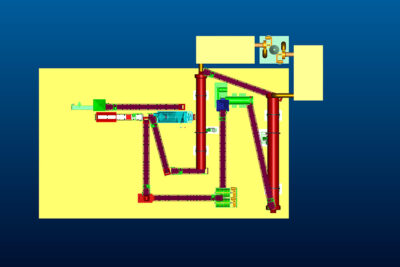

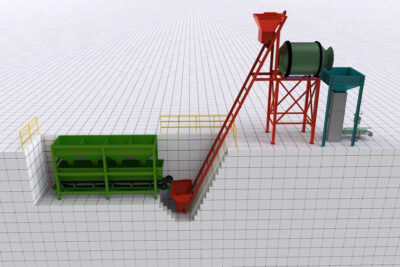

The disc granulator produced by our factory (also known as a ball-forming disc, disc granulator) has the characteristics of simple structure, low cost and convenient maintenance. Physically crushed separately in the pulverizer, mixed in the mixer after metering or batching, conveyed to the top of the disc by a belt conveyor, and continuously and quantitatively added to the shallow plate, the raw materials in the shallow plate are bonded by the sprayed adhesive. Pan Granulator for Sale is wrapped into granules and tumbles in the disk as the disk rotates, gradually increasing. Due to the automatic classification ability of the disc during rotation, the large particles float on the top and are continuously discharged from the bottom of the disc, until removed.

The main structure of the disc granulator machine for sale

- The disc granulator is composed of a large plate, a large gear, a transmission part, a frame, a base, a scraper frame, a powerless scraper, etc.

- The main body of the disc granulator includes a frame, an adjustment part and a granulating disc and other structures;

- The large disc is composed of a disc body and a disc segment, which reduces the power of the main motor. The disc segment can be adjusted up and down along the disc body. The end of the disc segment is an edge flange crack.

- The inclination of the large plate can be adjusted. The angle washer is adopted, and the adjustment is flexible and convenient, and the auxiliary power consumption is reduced by the unique integration of the unpowered combined scraper.

- One main reducer and one pinion gear on the output shaft;

- One main motor and one pulley;

- Supporting granulation disc device, including one main shaft, two sets of roller bearings, two sets of bearing seats

- The bottom of the ball-forming plate is reinforced with multiple radiating steel plates, which have high strength and rigidity;

- The transmission gear adopts high-frequency quenching treatment, which has a long service life;

- The reducer and the motor are driven by chain, with stable start, small impact force and high efficiency;

- The transmission system is equipped with a bridge device, which reduces the direct impact of the gear and the reducer, improves the operation stability of the equipment, and improves the service life of the main components;

- The unique unpowered combined scraper device is adopted to reduce the auxiliary power consumption

Pan granulator machine working principle

- The angle of the granulation disc adopts an overall arc structure, and the granulation rate can reach more than 93%.

- The granulating disc is equipped with three discharge ports, which is convenient for intermittent production operations, greatly reducing labor intensity and improving labor efficiency.

- The bottom of the granulating plate is reinforced with a number of radiant steel plates, which is sturdy and durable. Heavy, thick and sturdy base design, no need for anchor bolts, and stable operation. The main gear of the granulator adopts high-frequency quenching, and the service life is doubled.

- The granulated face plate is lined with high-strength FRP anti-corrosion and durable.

- The disc granulator has the advantages of uniform granulation, high granulation rate, stable operation, sturdy and durable equipment, and long service life. It is an ideal equipment for the majority of users.

Advantages and scope of application of disc pelletizer

- Normal temperature granulation, one-time molding, less investment and good economic benefits.

- Small power, reliable operation, no three wastes discharge, stable operation, convenient maintenance, reasonable process layout, advanced technology and low production cost.

- Wide adaptability of raw materials, can be used for granulation of various raw materials such as compound fertilizer, medicine, chemical industry, feed, coal, metallurgy, etc., and can produce various concentrations and types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.) compound fertilizer.

- In particular, the granulation of rare earth, ammonium bicarbonate and ammonium sulfate compound fertilizers fill the domestic gap and ranks at the leading domestic level. It is a promotion project of national environmental protection applicable technologies.

How to make quality fertilizer granules with the pan pellet making machine?

In terms of the material feeding amount of the disc granulator, it is best to uniformly feed the material, and it cannot be fast or slow. Adjust the nozzle. According to the mechanical principle, under the same pressure, the nozzle of the nozzle has a small nozzle hole, a small droplet density, a large nozzle hole, and a large droplet density. Strictly control the amount of water spray and adjust the appropriate amount of water to effectively improve the rate of ball formation and output. Unpowered or powered scraper assistance can also be added. The size of the machine, the rotational speed of the disc, and the inclination of the disc are also factors that affect the granulation effect.

Due to its simple structure, low price, and little maintenance, the disc granulator is not only used for the production of organic fertilizers, but also widely used for conveying various non-sticky materials in powder, material or small pieces, such as pulverized coal, Cement, clinker, fertilizer and other materials.

Technical specifications for the pan plate granulation equipment

| Model | Bottom Plate Thickness (mm) | Hoarding thickness (mm) | Hoarding height (mm) | Granulation output (t/h) | Reducer model | Rotation speed (r/min) | Dimensions (L×W×H) (mm) |

| YZ-500 | 6 | 3 | 200 | 0.02-0.05 | BWY0-43-0.55kw | 32 | 600×600×800 |

| YZ-600 | 6 | 3 | 28 | 0.05-0.1 | BWY0-43-0.55KW | 33.5 | 800×700×950 |

| YZ-800 | 6 | 3 | 200 | 0.1-0.2 | XWD4-71-1.5KW | 21 | 900×1000×1100 |

| YZ-1000 | 8 | 4 | 200 | 0.2-0.3 | XWD4-71-1.5KW | 21 | 1200×950×1300 |

| YZ-1200 | 8 | 4 | 250 | 0.3-0.5 | XWD4-71-1.5KW | 21 | 1200×1470×1700 |

| YZ-1500 | 8 | 4 | 300 | 0.5-0.8 | XWD5-71-3KW | 21 | 1760×1500×1950 |

| YZ-1800 | 8 | 6 | 300 | 0.8-1.2 | XWD5-71-3KW | 21 | 2060×1700×2130 |

| YZ-2000 | 8 | 6 | 300 | 1.2-1.5 | XWD5-71-4KW | 21 | 2260×1650×2250 |

| YZ-2500 | 8 | 6 | 450 | 1.5-2.0 | ZQ350 | 14 | 2900×2000×2750 |

| YZ-2800 | 8 | 6 | 400 | 2.0-3.0 | ZQ350 | 14 | 3200×2200×3000 |

| YZ-3000 | 8 | 6 | 450 | 2-4 | ZQ350 | 14 | 3400×2400×3100 |

| YZ-3600 | 14 | 8 | 450 | 4-6 | ZQ400 | 13 | 4100×2900×3800 |