Rotary Drum Dryer for Sale

- Application: Medicine Processing, Chemicals Processing, Food Processing, fertilizer

- Voltage: 220v/380v

- Power: 5.5kw

- Dimension(L*W*H): 10×1.3×1.3m

- Weight (KG): 8000

- Core Components: Bearing, Gearbox

- Evaporation Capacity(kg/h): 1000

- Heating Method: Gas Heating

- Material: Other, Carbon Steel

Get Price Now!

Description

The rotary drum dryer is driven by a reduction device equipped with a variable speed mechanism. Except for special circumstances, the speed is mostly in the range of 4 ~ 6r/min. The material to be dried with the npk dryer drum is generally completed within 10-15s from cloth film to drying and discharging. The heating medium in the rotary drum drying machine mostly adopts steam of 2×105~6×105Pa, and its temperature is about 120~150℃. The scraping device consists of a blade, a support frame, a support shaft and a pressure regulator.

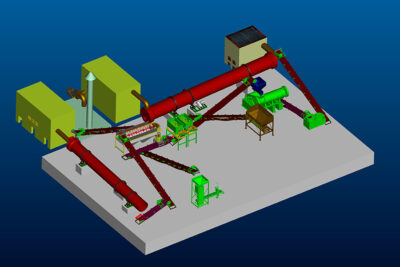

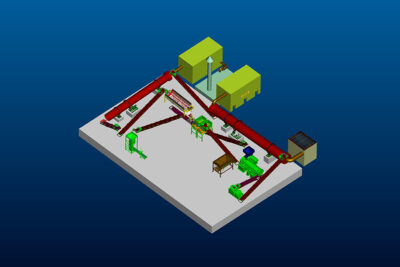

Rotary Drum Dryer for Sale in NPK Plant

According to the transmission method of the top tightening force on the scraper, it is divided into direct scraper type and lever type. There are two types of pressure regulators: elastic and rigid. The scraper device is generally installed in the third or fourth quadrant of the cross-sectional coordinates of the fertilizer dryer drum.

According to the length of the drum drying equipment, the scraper can be composed of single knife and combined knife. The single knife is suitable for organic npk fertilizer dryers with drum length less than 1500mm. While, the combined knife is used in dryers with poor film peeling and larger drum drying machine length. The choice of blade material should consider its rigidity, wear resistance and corrosion resistance. In the npk organic or compound fertilizer plant, when you make fertilizer granules by wet granulation method, it is necessary to buy a fertilizer drying machine for your fertilizer production line.

What’s the structure of the rotary drum dryer?

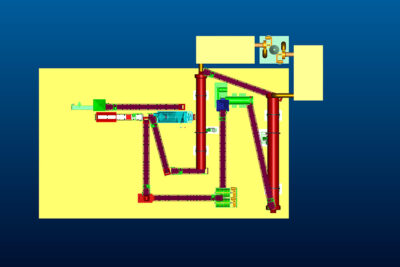

The rotary drum dryer is mainly composed of: rotating body, lifting plate, rotating device, supporting device, seal, ring and other components. It has the characteristics of reasonable structure, excellent fertilizer production, high product, low energy consumption and convenient operation.

Rotary Drum Drying Machine Working Principle

How does the rotary drum dryer work in drying npk granules? The working principle of the fertilizer dryer is very simple. The material enters the dryer drum from the bucket elevator, and then generates power through electricity, diesel power, wind power, flammable material power, etc. It uses the ambient air to heat npk granules. After drying, it will transport the fertilizer granules npk to the surrounding area to achieve proper temperature for dehumidification. Then, the raw materials will be into the rotary cooler.

Top 4 reasons to buy a rotary drum fertilizer dryer from our factory for your npk fertilizer production line

- The organic fertilizer rotary drum dryer has large operation flexibility and wide adaptability.

The operation flexibility of the organic fertilizer drum dryer is very large. Change one of the many factors that affect tumble drying without having other factors affect the drying operation. For example, several main factors that affect the organic fertilizer drum dryer are the temperature of the heating medium, the properties of the material, the thickness of the material film, and the rotational speed of the drum. Changing any of these parameters will have a direct effect on the drying rate, and there is no relationship between the factors. This brings convenience to the operation of the organic fertilizer drum dryer, so that it can use a variety of materials and different output requirements.

- The thermal efficiency of the organic compound npk fertilizer rotary drum dryer is high

The thermal efficiency of the organic fertilizer drum dryer is about 80% to 90%. This is because the heat transfer of the organic fertilizer drum dryer is heat conduction, and the heat transfer direction remains consistent throughout the operation cycle. Except for the heat dissipation and heat radiation loss of the end cover, the rest of the heat is used in the evaporation of water from the material film on the outer wall of the drum.

- The drying time of the organic compound npk fertilizer drum dryer is short

The wet material film formed on the outer wall of the organic fertilizer drum dryer at the beginning of drying is generally 0.5-1.5mm, and the entire drying cycle only takes 10-15s, which is especially suitable for drying heat-sensitive materials. After the wet material is dehydrated, it is discharged with a scraper, so the organic fertilizer npk rotary drum dryer is suitable for viscous slurry materials. It is more difficult to use other organic fertilizer dryer equipment for drying such materials. The organic fertilizer rotary drum dryer operated under reduced pressure can dry the material at a lower temperature. Therefore, organic npk fertilizer drum dryers are increasingly widely used in organic compound materials drying.

- The organic fertilizer rotary drum dryer has a large drying rate

Because the material film is very thin and the heat and mass transfer directions are consistent, the surface of the material film can maintain a vaporization strength of 30-70kg/h2o (m2·h).

Tumble dryer, also known as drum dryer or sleeve dryer, is the most common and widely used drying equipment in fertilizer production lines. High productivity and convenient operation, suitable for drying chicken manure granules, npk compound fertilizer granules, bio organic npk fertilizer pellets, etc.

How to install and debug the rotary dryer npk fertilizer production machine?

- The installation of the rotary dryer should be constructed in strict accordance with the requirements of the above assembly drawings and basic drawings. Before the installation of the rotary dryer, its parts and auxiliary parts should be checked and cleaned.

- Since the rotary dryer machine is a long and large-scale equipment, the installation should be carried out in this method:

(1) Draw the base line, correctly make crosshairs and elevation lines on the base mark, and embed the center mark to be convenient and accurate, and consider that the dryer machine base will not be covered after installation.

(2) Install the base and the tug to level the shoring iron position, draw out the base and the tug, according to the requirements of the drawings, find the installation position of the base and the tug, level and straighten. Grouting the foundation hole first. And when the concrete reaches a certain strength, tighten the anchor bolts, and then install the cylinder after passing the inspection.

(3) Install the cylinder body and the rolling ring for the rotary drum dryer. First install the rolling ring on the cylinder body. The concave joints required for fixing should be arranged in a positive and negative staggered configuration, and adjust the thickness of the pad iron to keep the contact between the rolling ring and the concave joint. The corresponding gap should not be consistent, and spot welding the head of the concave joint bolt and the cylinder.

- After the above work is completed, the secondary grouting shall be carried out. The requirements for grouting shall be carried out according to the relevant regulations of civil engineering design. The installation review and debugging work related to grouting are carried out simultaneously to ensure the installation quality of the dryer.

More detailed information about the fertilizer drum drying equipment, welcome inquiry us now.