Fertilizer Blender for Sale

-

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Powder or Granules Fertilizer Materials

- Industry Serviced: Organic Fertilizer Plant, Bio Fertilizer Plant, NPK Plant, Fertilizer Blending Plant

- Main Types:Pan Mixer, Drum Blender, Single, Double Shafts Mixer

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

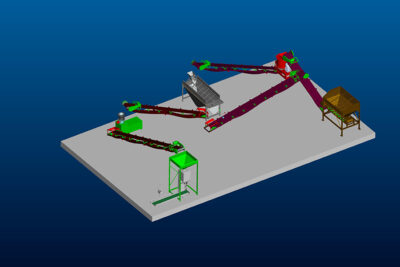

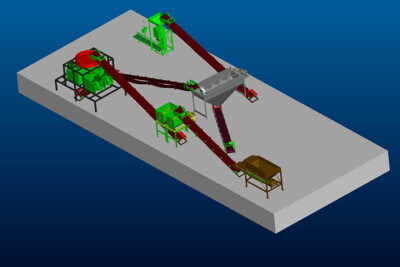

Fertilizer blender for sale in our company is specially designed for npk fertilizer plants. There are 6 types of fertilizer mixers are quite popular among our customers organic npk compound fertilizer production business. From small capacity ones, such as the pan mixer for sale, to the large capacity rotary drum blending equipment, there are always your suitable for your fertilizer production business. Whether you need to make organic npk mixers or compound fertilizer npk mixture, or bb fertilizer blends, our machines mixer can meet your npk production requirements at factory price. The top 6 popular sales fertilizer mixers are: pan mixers, single and double shafts mixers, horizontal blenders, bb fertilizer blending equipment and the rotary drum bulk blending machine for large npk mixing plants. Detailed info and technical specifications are as following for your reference.

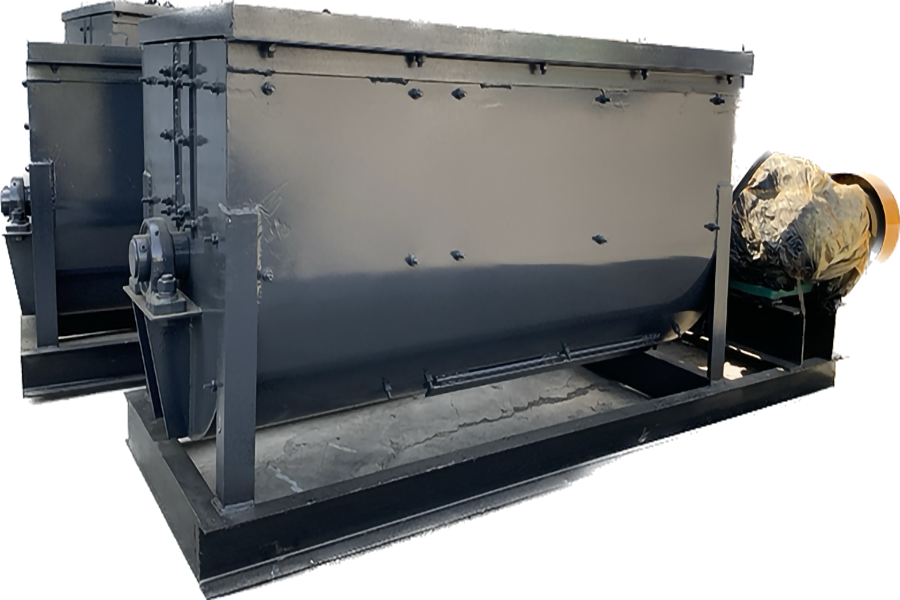

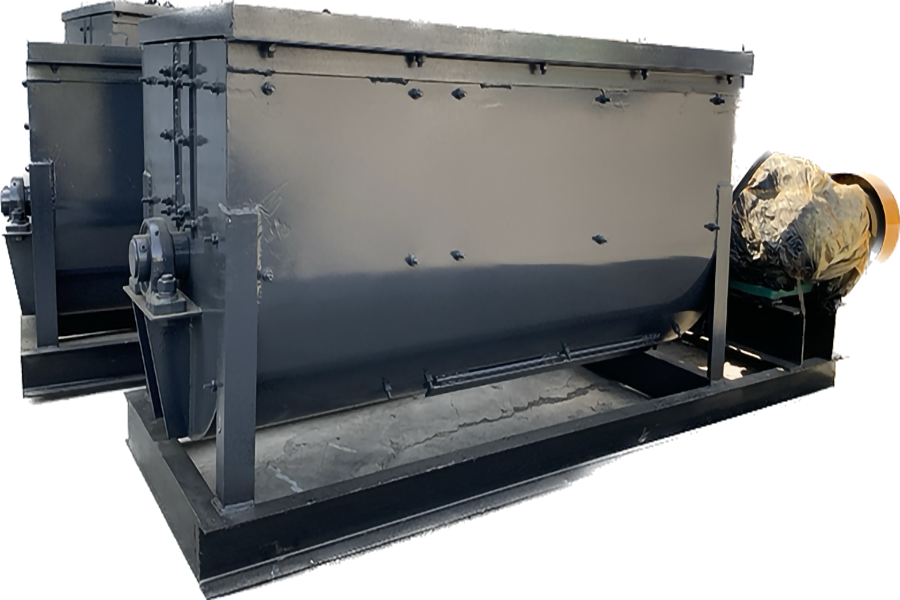

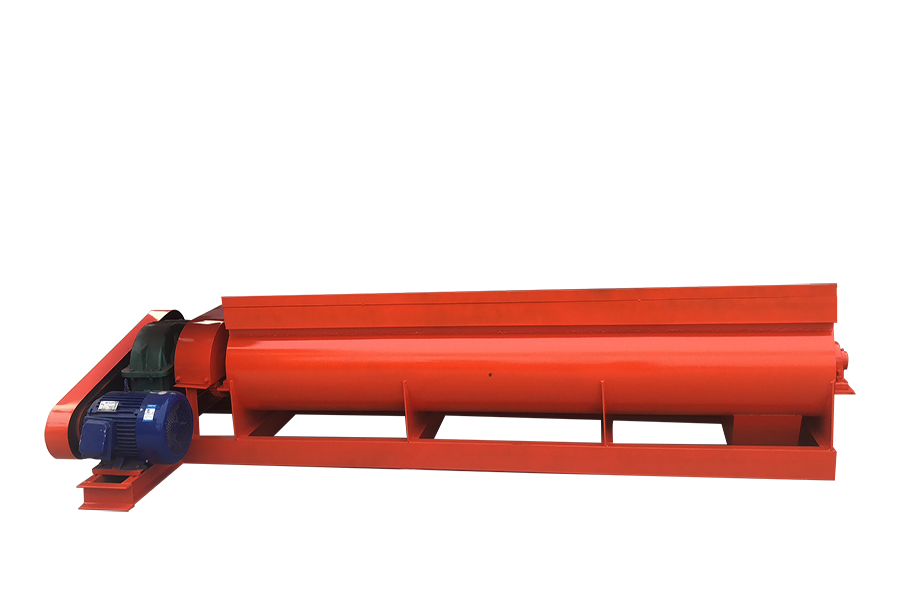

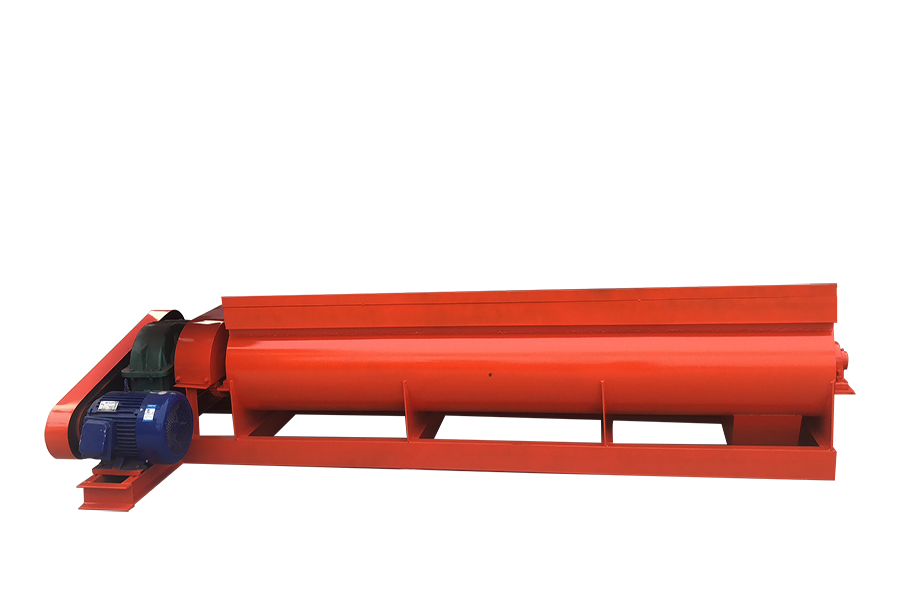

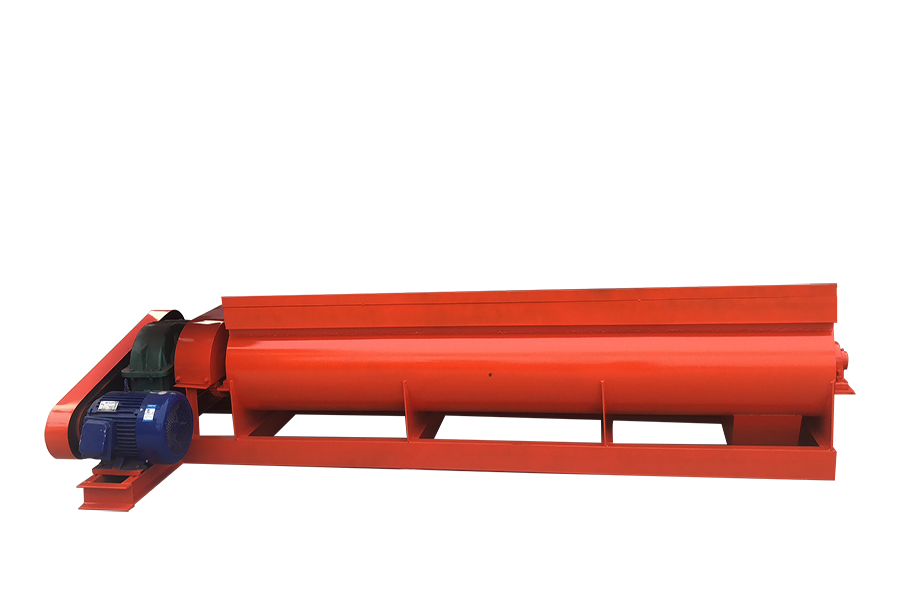

Horizontal Fertilizer Blender for Sale in Organic NPK Fertilizer Production Line

Horizontal fertilizer mixer for sale in our company is quite popular among our customers in organic compound npk fertilizer production industry since its high mixing efficiency and less space occupation. How to mix npk powders with the horizontal blender? When horizontal mixer working, the material in the machine is operated by two opposing rotors. By this way, the compound motion is carried out. The blade drives the material to rotate counterclockwise along the inner wall of the machine groove. On the one hand, it drives the material to turn around, forming a weightless zone outside the overlap of the two rotors. In this area, no matter the shape, size and density of the npk powder inputs material, the material can be floating in an instantaneous weightlessness state. This makes the material in the machine groove form an omni-directional continuous loop, alternating shear, so as to achieve fast and soft mixing uniform effect. Customers want to mix 1t to 15 t per hour npk fertilizer mixers, choose this type of mixer will be your best choice. There are three capacities in our factory, 1t to 3t per hour horizontal mixers for small capacity npk production lines, 3 to 5 t capacities per hours for medium npk production factories. While for large scale compound fertilizer production lines, there are 10t to 15 t per hour capacities available for your fertilizer production project.

NPK Horizontal Blender Technical Design Specifications

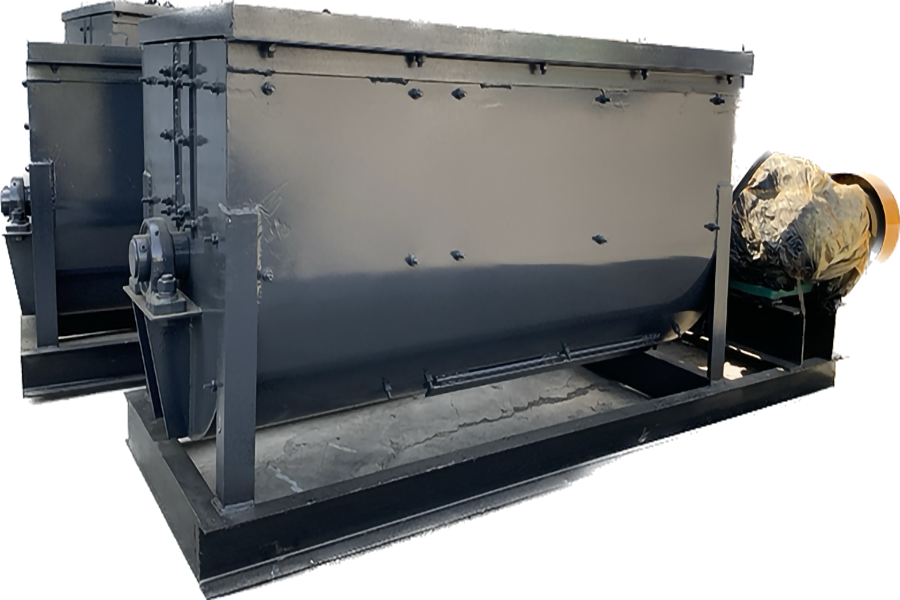

Double Shafts Mixers for Sale in Continuous NPK Fertilizer Blending Process

In the npk fertilizer mixing process, a continuous is quite important for automatic npk fertilizer production. Double shafts horizontal mixer is suitable for continuous mixing of mixed npk fertilizer powder. These types of fertilizer mixing machine usually can be used after automatic batching equipment. Which quite important for organic, bio npk compound fertilizer production. The working principle of the double shafts blender is that the materials go into the fertilizer mixing tank, then through a pair of screw shafts with opposite rotating, they are stirred uniform. When fully and evenly mixed together, raw materials can be perfect for the next npk granulation process.

Fertilizer Blending Equipment Single Shaft one for NPK Mixing Plant

Compared to the double shafts mixer, there is one shaft or paddle in the single shaft fertilizer mixer machine. It is suitable cost-effective mixing in npk compound fertilizer production. For customers with low budgets and want to make npk blends at low cost, this type of mixer will be your nice choice than the double shafts one.

BB Fertilizer Blending Machine for Mixed NPK Production Process

Other than the above-mentioned mixer, raw materials for bb blending are usually uniform npk granules. BB fertilizer mixer overcomes the mixtures chromatography and distributaries phenomena caused by different proportion of raw materials and particle sizes in npk blends production. Thus, it improves the dosing accuracy in the granulation process. Meanwhile, it also solves the influence on system caused by material properties, mechanical vibration, air pressure, voltage fluctuation cold weather etc. It has the characteristics of high precision, high speed, long life, etc., which is the ideal choice in BB (mixed)fertilizer producer.

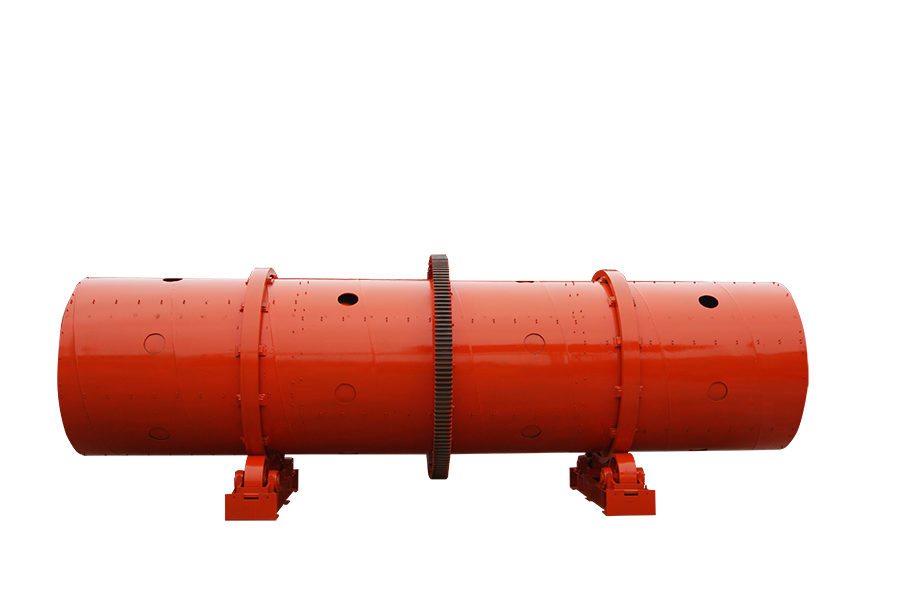

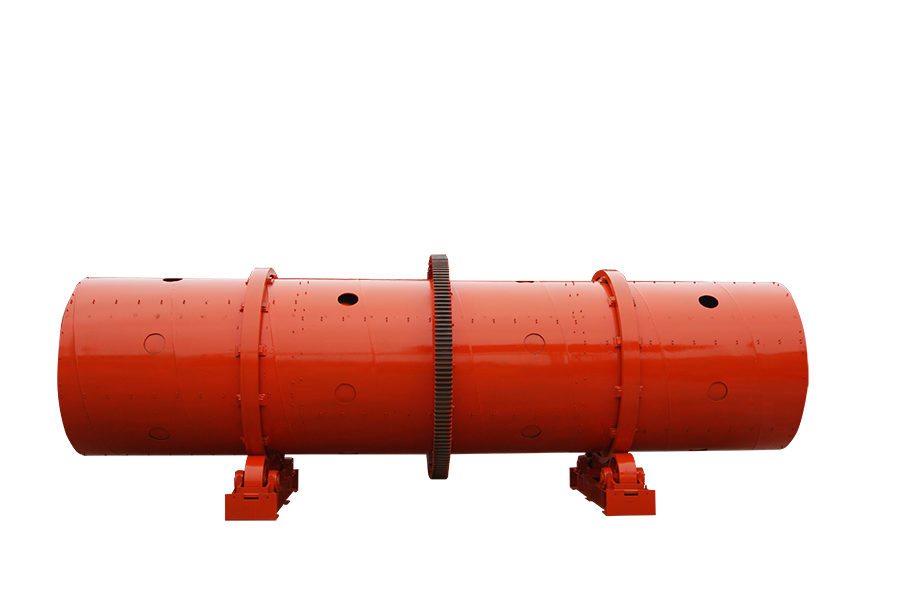

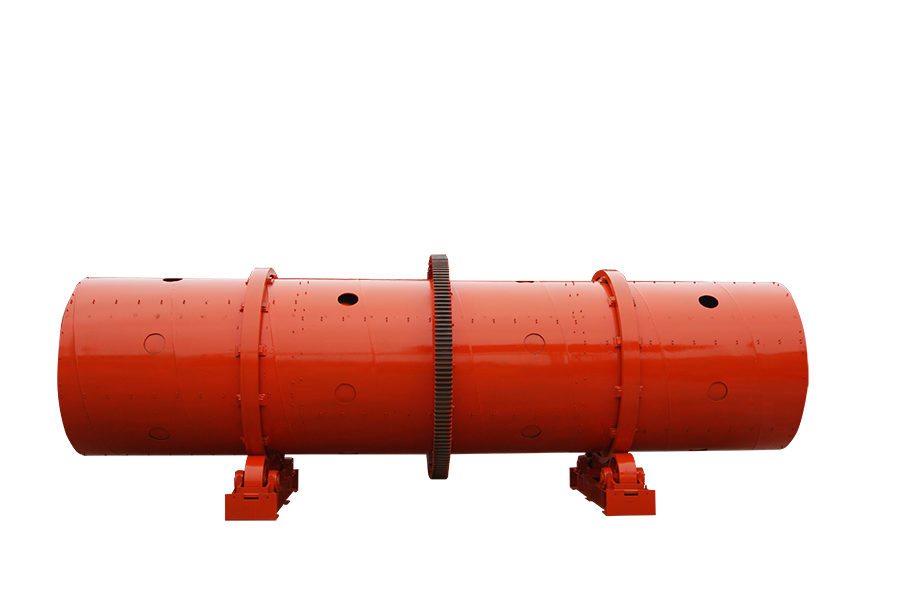

Rotary drum mixer for npk bb fertilizer production

Compared to the above bb mixer, this drum mixer’s production capacity reaches 30t to 40t per hour. For customers, want to make bulk npk blending fertilizer at large scale, you need not to buy too many mixers, only equipment one for your npk production factory, it will be suitable. In-lined with abrasion materials in the drum, you can use it for a longer time than traditional fertilizer mixers.

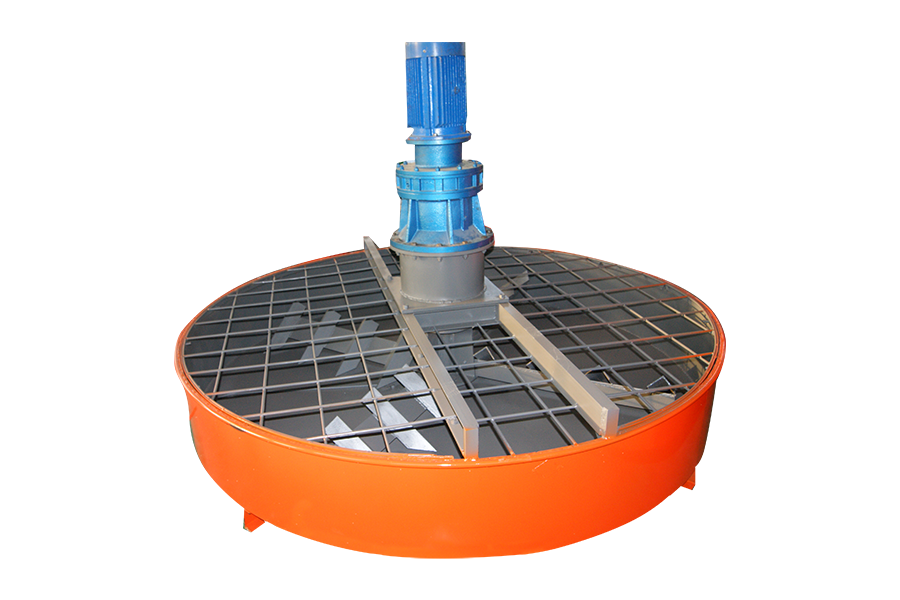

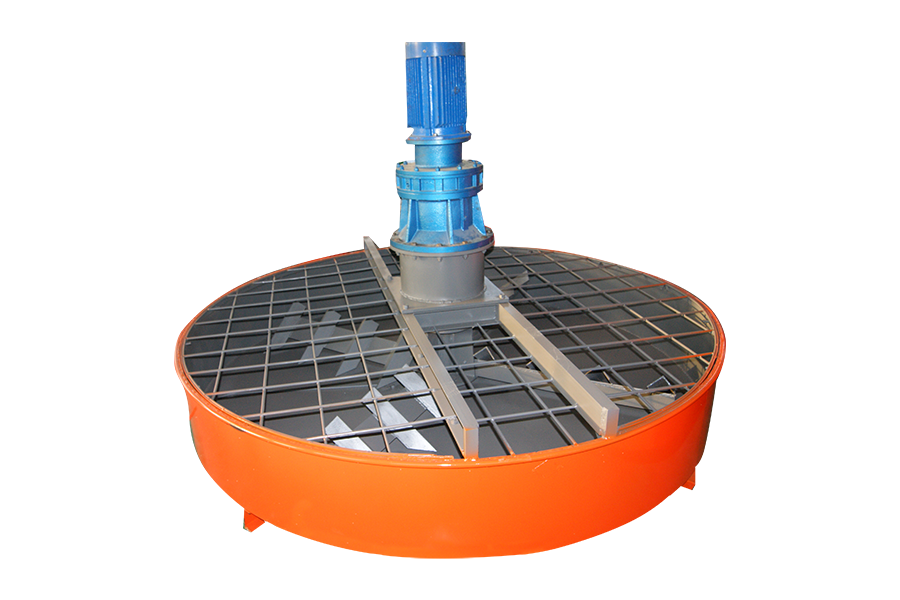

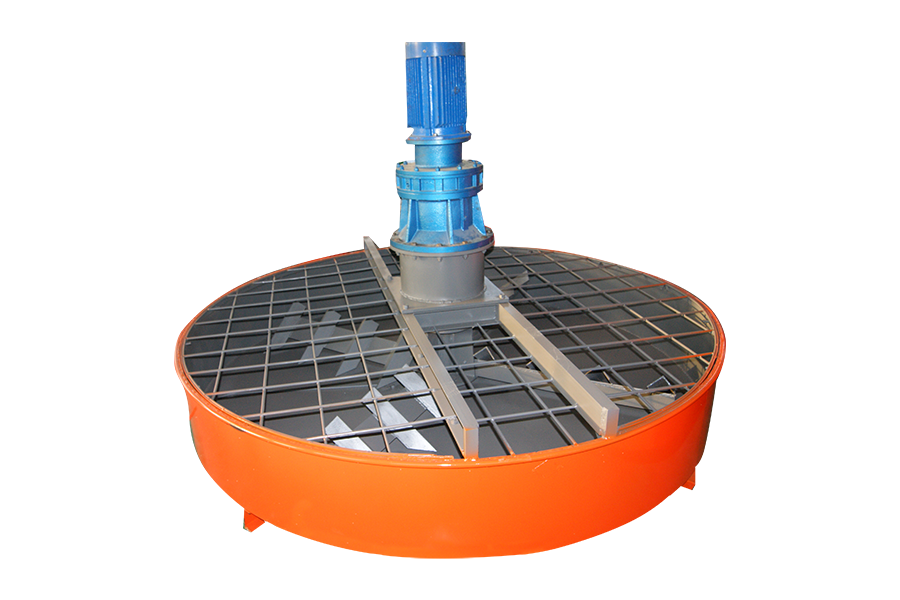

Pan Vertical Mixers for Small capacity NPK Fertilizer Production Business

Vertical disc mixer is a special mixer for npk compound fertilizer production industry. It is a kind of mixing equipment specially used for organic compound fertilizer mixer produced by our company. It is a low- cost mixer for customers small capacity organic and compound fertilizer production plants. It can also be used as a feeder machine in fertilizer production.

Reasons to buy a pan mixer for your small scale npk fertilizer plants

- 1.High mixing efficiency and less occupied area. The mixing blade adopts high-wear resistant special alloy.

- Easy to operate. The cycloidal gear reducer has the characteristics of compact structure, convenient operation, uniform stirring and convenient unloading etc. The rotation is smooth and the noise is low.

- Smart reasonable structural design. The disc mixer feeds material from top, discharge from bottom, which is reasonable.

- Stable run with less noise. The sealing between each combination surface is tight, so the machine can run smoothly. The rotation is smooth and the noise is low.

Technical specifications of the NPK Disc Mixer for Sale in Fertilizer Production Line

The above different types of fertilizer blenders for sale just for you reference. For more detailed info, on fertilizer blending equipment design, price, configurations and installations, welcome inquiry us now.