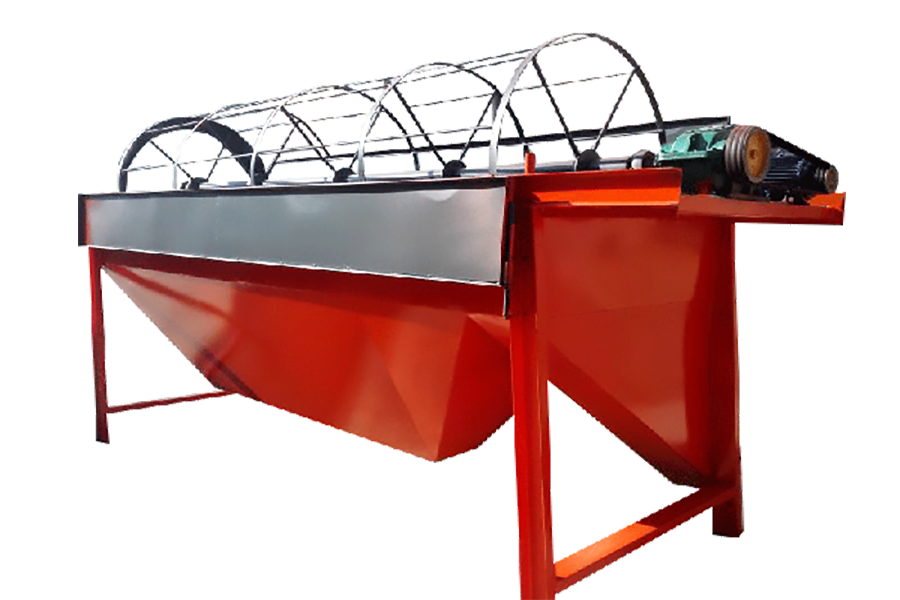

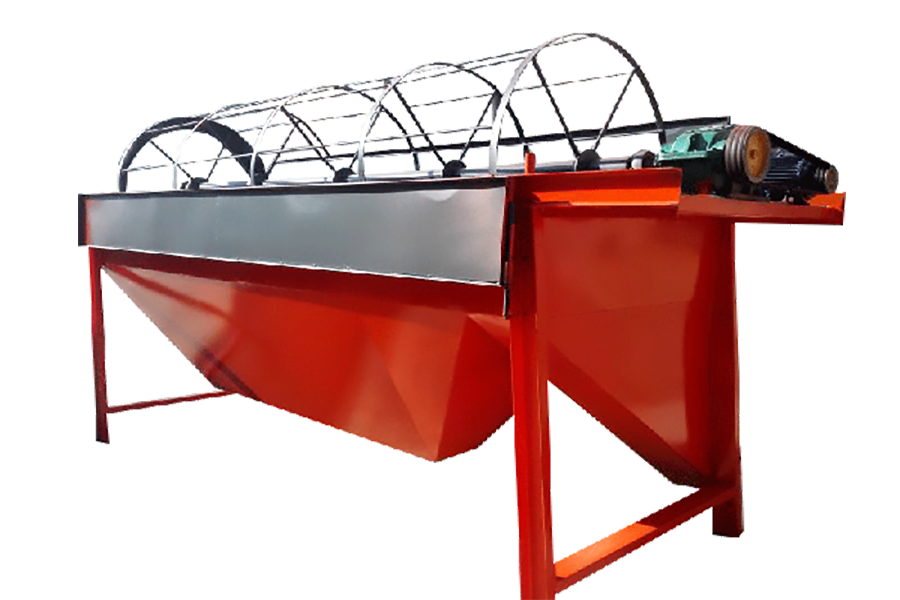

Rotary Drum Screener

-

- Production Capacity:1-30t/h

- Speed:8-20rpm

- Screen Bin:1 to 4

- Voltage:220v/380v/Customized

- Weight:1000kg

- Available Materials: animal manure., composts, powder, granular fertilizers,etc.

- Applicable Industries: organic fertilizer plants, bio fertilizer production lines, npk plants, bb fertilizer plants, etc.

- Video Outgoing Inspection: Provided

Get Price Now!

Description

Rotary drum screener machine is a key equipment in the organic npk fertilizer production plants. There are powder screener drums and granular rotary screening equipment available for your compound fertilizer production project. Powder fertilizer screener is specially for powder fertilizer production lines. While the granular fertilizer drum siever are best for fertilizer granulation plants. Only buying a rotary drum screener, can you make quality powder or granular fertilizer products in your fertilizer factory. There are 1t to 30t per hour capacity production drum sieving equipment available for your fertilizer screening from small to large scale.

Rotary drum screener main structure

For your quality fertilizer production process, we design you a high-quality rotary drum screening fertilizer machine at its every part. The combined screen is used for easy maintenance and replacement in the main part of the screen machine. With simple structural design, it can let operate it you conveniently. Additionally, it will be more stable operation when it screens powder or granular fertilizer products. To extend the rotary screener’s service life, we use steel plate and channel steel when welding manufacturing process. Combined screens in the transmission system, it helps you make quality fertilizer efficiently with less manpower costs. While the pin-type connector to phase teeth and transmit the drive system design, it is quite convenient for assembly and maintenance.

Tips to operate the drum fertilizer screener in npk fertilizer production line

In the npk fertilizer production line, it is quite important to let every machine works normally. The following 5 tips for you to work the rotary drum screener easily.

1. When using the drum screening rotary machine, you should start it with no-load. This will let you make final fertilizer npk granules easily.

2.Check all bolts for looseness before starting the screener rotary drum machine. It will let you operate is safely.

3. Check whether the oil level in the bearing housing and in the reducer is in place. This process is quite important for your efficient npk manufacturing process.

4. Start the main motor, check whether the rotation direction is opposite, if it is in the opposite direction, stop and adjust immediately. Whether your drum fertilizer sieving machine work, the motor is the key.

5. Stop feeding materials before turnoff the rotary drum screener. It is strictly forbidden to park with materials.

Technical specifications for the drum fertilizer screening equipment in powder and granular fertilizer production lines

[table “DrumScreener” not found /]The above information about the structural design, using tips and specifications, just for your reference in fertilizer production plants. For more details in prices lists, and costs, welcome inquiry us now.