Rotary Drum Cooler for Sale

- Application: Medicine Processing, Chemicals Processing, Food Processing, fertilizer

- Voltage: 220v/380v

- Power: 5.5kw

- Dimension(L*W*H): 10×1.3×1.3m

- Weight (KG): 8000

- Core Components: Bearing, Gearbox

- Evaporation Capacity(kg/h): 1000

- Heating Method: Gas Heating

- Material: Other, Carbon Steel

Get Price Now!

Description

The drum cooler is used for cooling the fertilizer of a certain temperature and particle size in the compound fertilizer production process. And it is always used in conjunction with the rotary drum dryer. Our drum cooling equipment greatly improve the cooling speed, reduce labor intensity and increase output.

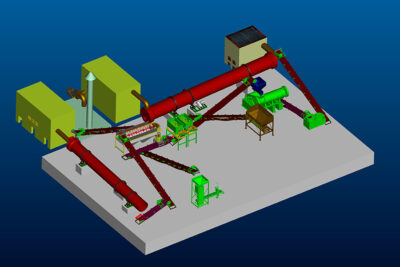

Rotary Drum Cooler in npk manufacturing plant

Rotary Drum Cooler further removes part of the water and reduces the grain temperature of the npk compound fertilizer granules. At the same time, it can be used for cooling other powdery or granular materials. The cooling rotary machine has compact structure, high cooling efficiency, reliable performance and strong adaptability.

How to cool npk fertilizer granules with the rotary drum cooler? (Working Principle)

The rotary drum cooler is mainly used to cool the fertilizer materials after drying. When the hot npk granules enters the drum cooler from the feed port, the deceleration motor drives the drum to rotate, the copying plate in the cooler drum turns the fertilizer granules. And the natural cooling air enters from the discharge port to fully contact the material. Hot air is discharged from the air outlet. The countercurrent method is adopted to cool the dry material, and the fan end is connected to the dust collector to prevent dust from flying. To buy a npk drum cooling machine for your npk fertilizer plant, it will help you make quality fertilizer products efficiently.

Main Structures for the rotary drum cooler machine for sale

The whole npk fertilizer cooling machine can be divided into five parts:

Bracket part: The whole rotating part of the cooling fertilizer machine body is supported by the bracket, and the force is large. Therefore, the supporting parts of the cooler drum machine are all welded with medium carbon steel plates and channel steel. What’s more, they have passed strict quality control and special process requirements, which have achieved the purpose of this machine. In addition to this, the more important thing is the supporting roller fixed on the shelf. Considering the large friction between it and the rolling belt of the body, our factory specially chooses anti-corrosion and wear-resistant materials, which greatly improves the service life of the fertilizer cooling machine. The frame also adopts casting integrated technology. In addition, there are hoisting hooks at the four corners of the supporting wheel frame, which is convenient for loading, unloading and transportation.

Transmission part: The transmission part of the whole rotary cooler is the most important work of the whole body. The transmission frame is welded by channel steel and has passed strict quality requirements. The main motor and reducer installed on the transmission frame are ISO products with reliable performance and reliable quality. The motor drives the pulley, the V-belt and the reducer to transmit to the main shaft, so that the body works. The transmission reducer is connected to the working part of the main shaft by using a nylon log-off coupling to engage and transmit the drive.

Large ring gear: It is fixed on the machine body and meshes with the transmission pinion to drive the machine body to work in the opposite direction. It uses high-tech wear-resistant materials to make the machine last longer.

Rolling belt: fixed on both sides of the body to support the whole body.

Body part: The most important part of the whole cooler is the body part, which is made of medium carbon steel.

The plate is welded, the built-in lifting plate is made of wear-resistant material, the distribution and angle design are reasonable, and through strict quality control and specific process requirements, the material is lifted to form a curtain to achieve the purpose of heat dissipation and water powder.

Technical specifications for the rotary drum cooling equipment

| Model | Inner Diameter(M) | Drum Length(M) | Rotation Speed(r/min) | Feeding Temperature(°C) | Output Temperature(°C) | Power(kw) | Capacity(t/h) |

| LQJ 0.8X10 | 0.8 | 10 | 4.6-5 | 60-80 | 40 | 5.5 | 1-2 |

| LQJ 1X10 | 1 | 10 | 7.5 | 2-2.5 | |||

| LQJ 1.2X12 | 1.2 | 12 | 11 | 1.5-3.5 | |||

| LQJ 1.5X12 | 1.5 | 12 | 15 | 3-4 | |||

| LQJ 1.8X18 | 1.8 | 18 | 18.5 | 4-5 |

More detailed information about the rotary drum cooling machine prices and costs, get inquiry now.