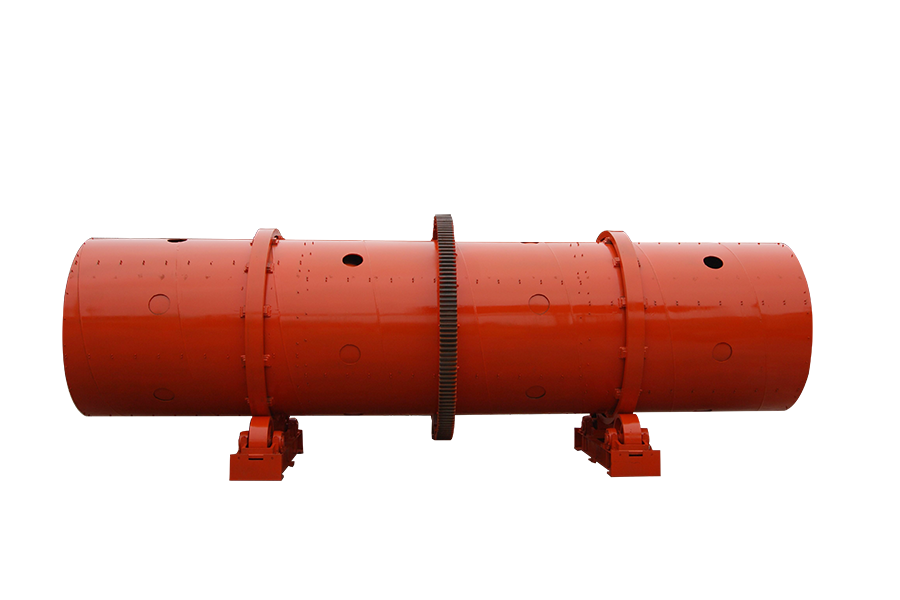

Rotary Drum Granulator for Sale

- Output (kg/h):2000

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Voltage: 220/380v

- Dimension(L*W*H): 1200*4000*1800mm

- Weight (KG): 168

- Power (kW): 55

- Applicable Industries: Farms, Chemical & Machinery Equipment

Get Price Now!

Description

Rotary drum granulator fertilizer machine is a new generation of rotary drum granulator developed by our company staff with years of experience in compound fertilizer production. This machine has the characteristics of beautiful appearance, simple operation, low energy consumption, long life, uniform drying, convenient maintenance, etc.

Rotary Drum Granulator for Sale is the most advanced granulation equipment in China. This product is suitable for cold and hot granulation and high, medium and low concentration compound large-scale production of mixed fertilizer, the product is now all over the country.

The main features are as follows:

- Less investment, quick effect, good economic benefit and reliable performance;

- Small power, no three wastes discharge, stable operation, convenient maintenance, reasonable process layout, advanced technology and low production cost;

- High ball strength, good appearance quality, corrosion resistance, wear resistance and low energy consumption;

- The cylinder body is lined with special rubber plate or acid-resistant stainless-steel lining, which realizes automatic scar removal and tumor removal, and cancels the traditional scraper device;

Granulator drum working principle:

The working principle of this series of granulator drum is: the main motor drives the belt and pulley, and the drive shaft is driven by the reducer, and the split gear installed on the drive shaft is connected to the large ring gear fixed on the body. Work together. The material is added from the feed end and passes through the inside of the cylinder. Under the action of the special structure inside the cylinder, it is made into granules, and then flows out through the discharge port. Due to the continuous entry of materials and the continuous rotation of the granulator, mass production can be achieved.

Features of rotary drum granulator for sale:

- The rate of ball formation is 70%, there is a small amount of returned material, the particle size of the returned material is small, and it can be re-granulated;

- Pour in steam to heat to increase the temperature of the material, so that the moisture content of the material is low after the material is formed into a ball, and the drying efficiency is improved;

- The rubber engineering plastic is used as the inner lining, the raw material is not easy to stick to the cylinder, and it has the effect of anti-corrosion and heat preservation;

- Large output, low power consumption and low maintenance cost.

Advantages of rotary drum granulator:

The main advantage is that the use of steam to heat and adjust humidity increases the temperature of the granulated material itself, reduces the moisture content of the granulation, reduces the load of the dryer, and improves the work efficiency. The granulation rate of the rotary drum granulator can reach 70%, and the equipment is simple to operate, has large working flexibility, and is easy to maintain. The equipment is lined with ultra-high molecular weight polyethylene (UHMW-PE), which eliminates the phenomenon of material sticking to the wall, reduces the labor intensity of workers, and greatly prolongs the service life of the equipment. Mainly used for granulation in compound fertilizer production line.

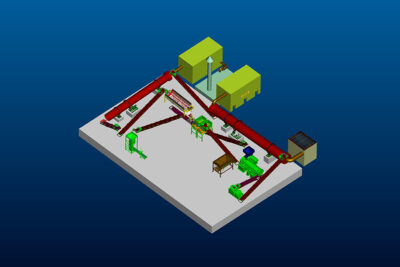

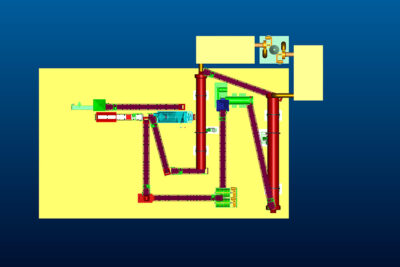

Brief introduction to the production process of compound fertilizer by steam drum granulation:

- After crushing, the qualified raw materials such as nitrogen, phosphorus, potassium and filler are sent to the automatic scale for weighing;

- The weighed raw material enters the raw material mixer and is vigorously stirred evenly;

- It is transported to the drum granulator, and saturated steam (or water) is introduced at the same time. The material forms a rolling material bed with the help of the friction generated by the rotation of the drum granulator. The material in the liquid phase agglomerates into small particles, these small particles become the core, and the surrounding powder adheres to form qualified particles;

- It is transported to the rotary dryer for heat exchange with the heat from the hot blast stove;

- The particles are transported to the hot sieve for sorting, and the fine particles are directly returned to the drum granulator, as the core to continue to participate in the adhesion of the particles into balls;

- The semi-finished granules after screening are transported to the rotary cooler, and the fertilizer is cooled by natural cold air or forced cold air;

- Transported to the finished product screening machine, the large particles are crushed by the fertilizer pulverizer and returned to the drum granulator to continue to participate in ball formation;

- The qualified products after screening are sent to the coating machine for coating treatment;

- Transport to the automatic packaging scale for weighing, packaging and storage;

- Drying, cooling and workshop dust are emptied up to the standard after three-stage treatment by cyclone dust collector, labyrinth dust removal chamber and wet washing.

Some operational indicators of compound fertilizer production by steam drum granulation:

- The amount of urea is 3~9%, and the temperature at the end of the dryer is controlled at about 65°C.

- The amount of urea is 10~20%, and the temperature at the end of the dryer is controlled at about 60.

- The amount of urea is 21~38%, and the temperature at the end of the dryer is controlled at about 55°C.

- During granulation, the particle diameter is controlled at 1~2mm, accounting for 30%, and 2~4mm accounting for 60%.

- Sandy raw materials (potassium chloride, potassium sulfate, ammonium chloride, ammonium sulfate, etc.) account for more than 35%, and the fineness is more than 60 mesh.

- The granulation temperature is controlled at 60~65℃.

Technical Specifications for the rotary drum granulation equipment

| Model | Drum | Capacity | Reducer Model | Motor Power | Weight | |||

| Inside Dia. | Length | Angel | Rotation Speed | |||||

| m | mm | mm | ° | r/min | t/h | kw | t | |

| Φ1.4*4 | 1400 | 4000 | 2.5 | 15.05 | -5 | JZQ500 | 11 | 8 |

| Φ1.6*6 | 1600 | 6000 | 2.5 | 12 | -7 | JZQ500 | 15 | 11 |

| Φ1.8*6 | 1800 | 6000 | 2.5 | 11.5 | -8 | JZQ650 | 15 | 16 |

| Φ2.0*7 | 2000 | 7000 | 2.5 | 10.8 | -14 | JZQ650 | 30 | 25 |

| Φ2.2*8 | 2200 | 8000 | 2.5 | 10.85 | -20 | JZQ650 | 37 | 29 |

| Φ2.4*8 | 2400 | 8000 | 2.5 | 9.6 | -25 | ZL750 | 55 | 42 |

| Φ2.8*8 | 2800 | 8000 | 1.5 | 6.5 | -35 | ZLY315 | 90 | 55 |