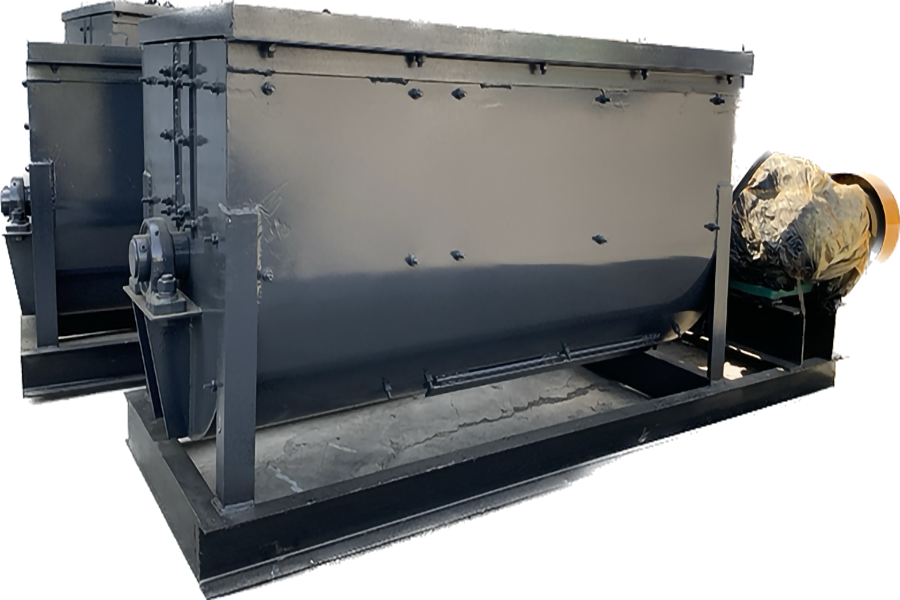

Horizontal Mixing Machine

- Mixer Type:Agitator

- Barrel Volume (L):1350 L

- Max. Loading Volume (L):1500 L

- Range of Spindle Speed(r.p.m):40 – 46 r.p.m

- Weight (KG):536 KG

- Material:SUS304, SUS316, Ti

- Voltage:380V

- Dimension(L*W*H):235*120*100CM

- Power (kW):7.5 kW

- Core Components:Gear, Gearbox, Bearing

- Stirring Speed:39r/min

- Body Thickness:4mm

Get Price Now!

Description

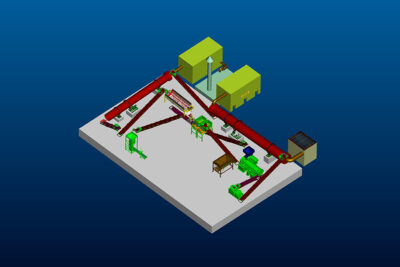

Horizontal Mixing Machine for Sale used in npk plant will help customers make commercial fertilizer efficiently. To make nutrient fertilizer, it needs to blend different types of fertilizer mixtures together. What’s more, sometimes, it needs to add some micro nutrients in the fertilizer mixture. Whether in powder fertilizer production line, or granular fertilizer production plant. it needs to mix all different nutrients. Then, you can make quality fertilizer to meet the market requirements.

Horizontal Mixing Machine for Sale in NPK Blending Plant

This horizontal fertilizer mixer relies on the action of the screw to make the npk raw materials continuously stir in the barrel to achieve the effect of mixing and color mixing. The barrel is made of stainless steel, stainless iron or iron plate. The materials are all according to customer requirements.

Horizontal compost mixer for sale in the bio compost fertilizer plant

In the compost fertilizer production process, when customers need to speed up the composting procedure, it needs to add some fermentation agents in the composters or the compost grooves. This time, it needs a compost horizontal mixing machine to mix the agents with the compost materials for rapid composting. While, some compost turners, like groove type compost turners, or in vessel composters, or crawler type windrow turners have such mixing function when they are in compost production.

Horizontal Fertilizer Mixing Equipment for Sale in Powder Fertilizer Production Line

After the composting process, there are some lumps or powder caking problems since the higher moisture content in the final compost fertilizer. To get evenly mixed fertilizer composts powder, you need to buy a horizontal powder mixer for your powder fertilizer production line. What’s more, to make powder fertilizer for commercial purpose, customers always add some bio-micro nutrients in the composts to make bio npk fertilizer. Thus, it is necessary equip a suitable horizontal powder mixing machine in the powder fertilizer production line.

Horizontal granular fertilizer mixier in the npk blending plant

Horizontal mixing machine are also applicable for npk fertilizer blending plant. The horizontal mixer will make npk fertilizer blends by continuous blending to the based granules with the uniform particle sizes. It is quite suitable for simple large scale fertilizer granular blending production plants.

The above are three different types of fertilizer blenders horizontal types in different fertilizer plants. The following are the main structures of horizontal mixing machine.

Structural designs for the horizontal mixing equipment

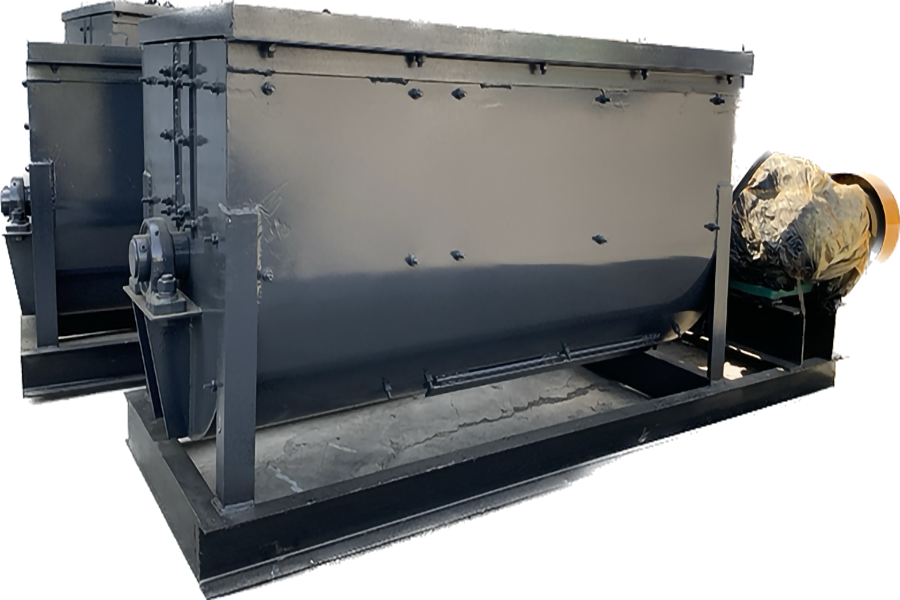

The horizontal mixer is divided into two categories: heating and drying and conventional stirring. It has a variety of capacity specifications for customers to choose. This series of models consists of: stainless steel “U”-shaped barrel, frame, transmission motor, S-shaped paddle shaft, heating device, dehumidification device and electric control box and other components.

Features:

- The heating and drying type adopts a double-layer U-shaped barrel design, and the inner wall is made of stainless steel:

- Using heat transfer oil as the heating medium, the heat is uniform and easy to control:

- The all-stainless steel central shaft and “S”-shaped paddles are sturdy and durable, and the homogenization effect is good:

- Select famous factory motors and reducers, with large output and stable performance:

- The screw feeder is purchased separately, eliminating the need for the feeding platform, which is safe, fast and convenient:

Fertilizer Horizontal Mixing Equipment Technical Data

| Model | WJ-70 | WJ-90 |

| Dimensions(mm) | 2350*1200*1000 | 2350*1200*1000 |

| Power(kw) | 7.5 | 11 |

| Reducers Model | ZQ350-23.34 | ZQ350-23.34 |

| Rotating Speed(r/min) | 46 | 39 |

| Plate Thickness(mm) | 4 | 4 |

| Capacity(t/h) | 2-3 | 3-5 |

Horizontal Fertilizer Blender Working Principle

The horizontal mixer uses a shaft equipped with a spiral blade to rotate. While conveying powdery materials such as dry ash, water is added and stirred to evenly humidify the dry ash powdery materials, so that the humidified materials do not emit dry ash and do not seep out water droplets.

Horizontal Blending Equipment Structural Design

This series of models consists of U-shaped or cylindrical barrels, racks, transmission motors, stirring shafts, heating/cooling devices, dehumidification devices, and electric control boxes.

Where can you use the horizontal mixing machine?

It is widely used in chemical, plastic, rubber, food, medicine, polymer, construction, fireproof materials and other granules, powder, liquid materials stirring and mixing.

How do we design you a high-performance fertilizer horizontal blender for sale?

Top 10 technical design highlights on the horizontal fertilizer mixer

- The equipment is made of different types of stainless steel such as carbon steel, SUS201, SUS304, SUS316L, etc. The material contact surface is stainless steel. The whole machine can also be customized to be made of stainless steel.

- Multiple models of stirring capacity are optional, and there are 50-20000L capacity specifications for customers to choose

- 3: The interior of the barrel is polished and smooth, and the blades are stirred without dead ends, and each batch can be mixed evenly in 5-10 minutes.

- All stainless-steel central shaft and single or double “S” shaped paddles, mix materials quickly and evenly;

- 5: The discharge port has turn-knife type, wall-mounted type, valve, manual, automatic (pneumatic, electric) waterproof, dust-proof and no leakage.

- Liquid addition atomization device: Our company has a patented product that can atomize liquid materials of different viscosities, so that the added liquid materials can be mixed more uniformly (spray-like).

- The heating and drying type adopts a double-layer U-shaped barrel design, adopts a 316 stainless steel heating tube for heating, and heat-conducting oil is used as the heating medium, so that the heat is uniform and easy to control; the drying and stirring are two-in-one, and the “heating switch” can be turned off to be used for material stirring. chemical use;

- Refrigeration type adopts double-layer U-shaped barrel design, usually continuous cooling with tap water, and the company’s special cooling water equipment can also be used. as low as minus zero. Provide environmental protection for special material mixing.

- The motor adopts high-quality 100% all-copper wire motor. Cycloidal pinwheel reducer, long life, low noise; or cylindrical gear reducer, large torque. The transmission parts are linked by industrial V-belts, and the replacement of accessories is convenient and quick.

- In addition, the company has screw feeders, vacuum suction machines, conveyor belts and other supporting facilities, minus the feeding platform, reducing labor intensity, saving time and labor. Safe, fast and convenient; there are automatic equipment such as storage barrels and automatic weighing and packaging systems at the back end.