Crusher Machine for Sale

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Animal Manure, Organic Compound Fertilizer Materials

- Industry Serviced: Poultry Farm Waste Management, Chicken Farm Litter Disposal, Fertilizer Plants

- Top Sale Crushers:Vertical, Chain, Straw, Hammer, Cage, Urea Crusher

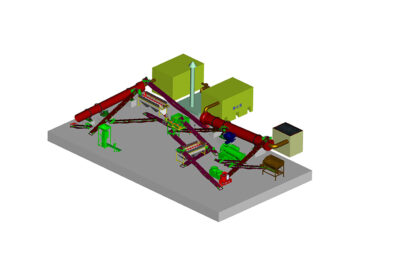

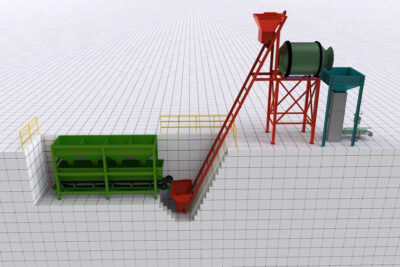

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

Crusher Machine for sale in our fertilizer production equipment manufacturing factory are specially designed for raw materials grinding in npk inorganic and organic production process. For organic natural npk fertilizer production plants, there are new type vertical crushers, semi-wet crushers and straw crushers, these three types of fertilizer crushers are specially used for organic materials processing in organic npk fertilizer production process.

While, the urea crusher, cage crusher, chain crusher, cage crusher and the hammer crusher are top sales grinders in compound npk fertilizer production materials processing. The following are detailed info of different types of fertilizer crushers for sale inn inorganic and organic compound npk fertilizer plant for your reference.

Why you need to buy a crusher for sale for your npk fertilizer production process?

Crusher machines are very necessary when you want to make quality npk fertilizer. Whether you want to make npk fertilizer inorganic type or organic types, before make quality npk fertilizer granules, the first step is to make fine powder from different lumps or solids of inorganic and organic fertilizer materials. Only by this way, the npk fertilizer granulation process shall be fluent and efficiency.

Crusher for sale using in manufacturing of npk fertilizer organic type

As the above mentioned, there are three types of crushers for sale in organic npk fertilizer production. The first is the new type vertical fertilizer crusher for sale, the second one is the semi-wet crusher, and the last one is the straw shredder for sale. The following are detailed info for your organic npk fertilizer production.

New type vertical crusher for sale in organic fertilizer production

The new type vertical crusher is a kind of adjustable fertilizer crushing equipment without screen cloth. It is designed on the basis of absorbing the advanced fine crushing equipments in domestic and abroad. Along with the semi wet manure grinders, and straw crushers machines, it is one of the fertilizer production equipment that can be widely used in organic npk fertilizer crushing.

It includes the following stunning features:

- Wide-spread applications: especially for high moisture organic npk material, like cow dung, chicken manure composts npk; it has strong application and is not easy to block, and the material discharging is smooth.

- Longer service life: crushing blade in the vertical crusher adopts quality carbon steel material, which makes its service life triple times than traditional crusher machine.

- Free of maintenance: equipped with observation window, it makes you replace the wearing parts in 10 minutes.

Technical specifications on organic npk vertical crusher for sale new developed design one

Top Sale Semi-wet Crusher for Sale in Organic NPK Manufacturing Process

Semi-wet material organic npk powder making machine is used in the crushing of high moisture material, like bio-organic npk compost fertilizer, manure compost, grass mud carbon, livestock and poultry droppings, etc. For most customers, they always choose this type of fertilizer crusher as their basic investments on the npk powder organic fertilizer making business. The minimum capacity of the semi wet grinder is 1t per hour which can meed small scale npk organic fertilizer production plants. With the maximum 8t per hour production capacity, it can also make npk organic powders at medium scale.

Semi-wet fertilizer crusher for sale in npk organic fertilizer plants parameters

Straw crushers for organic npk auxiliary materials pretreatment

In organic npk fertilizer production industry, to adjust the moisture and C/N portions in the npk production materials, straws from plants always be used as auxiliary materials. Before adding it to the fertilizer production process, it needs to crush first. Straw crusher is a new type fertilizer equipment produced by our company in the wood powder making machine market. The straw fertilizer grinder can guarantee standard rate of the finished product, which solves the inconvenience due to uneven fineness of finished product. Equipped with standard stainless-steel screen, it makes the outputs of the npk organic straw powder size optional. It has the advantages of small footprint, convenient packaging, simple operation and no dust pollution, which is the ideal crushing powder equipment for your npk organic materials pre-treatment.

What types of fertilizer crushers can be used for compound fertilizer production process plants?

Unlike organic npk materials, raw materials for inorganic compound npk fertilizer production are based chemical fertilizers. Thus, to make fine npk powder from them, it needs higher performance dedicated npk crushers in the compound npk fertilizer plants. In our npk fertilizer plant equipment production factory, there are three kinds of fertilizer crushers for sale, they are hammer mills, chain crushers and cage mill grinders. Detailed info are as follows:

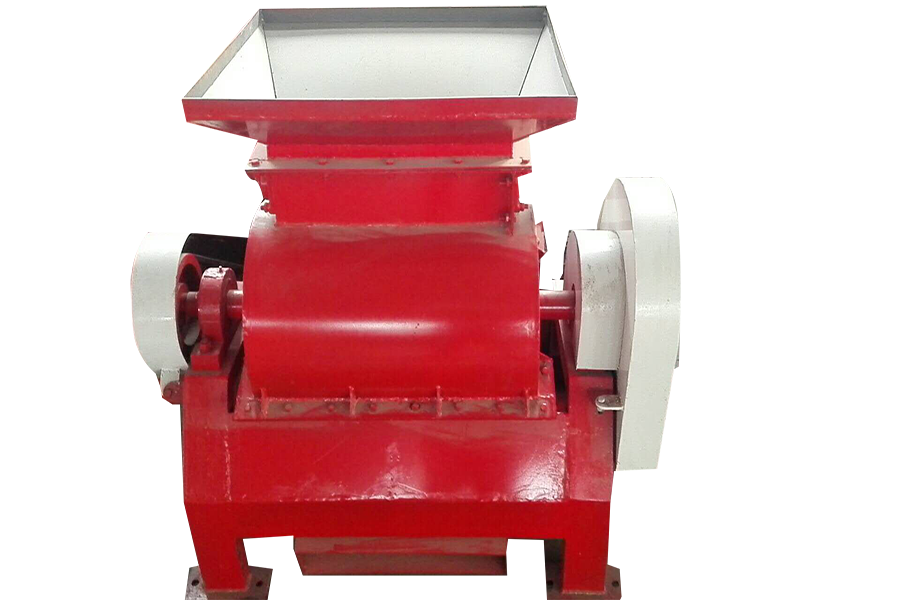

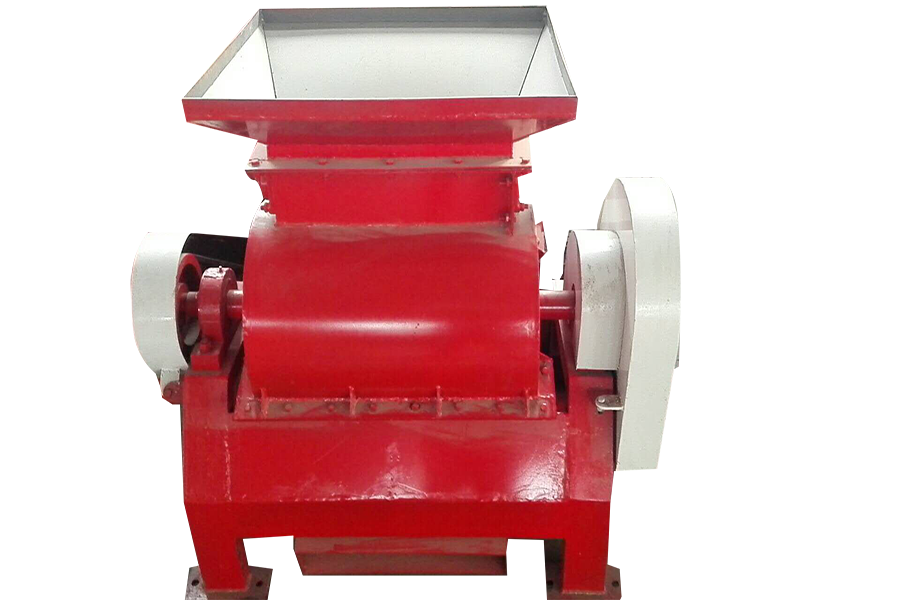

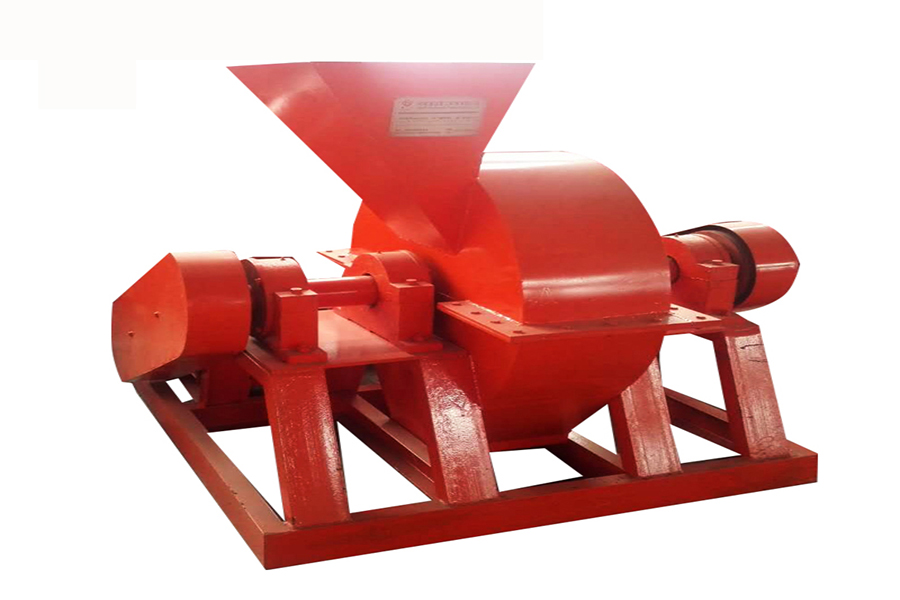

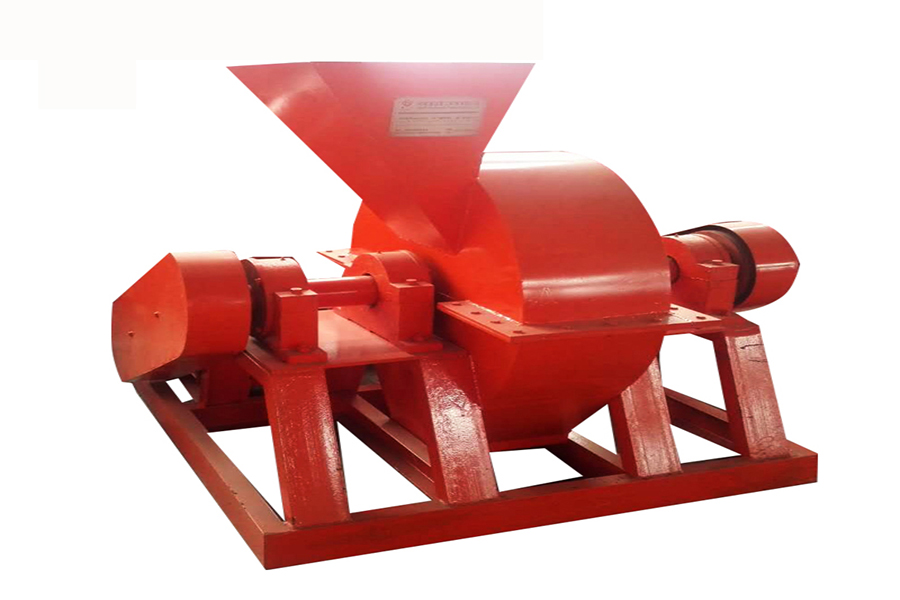

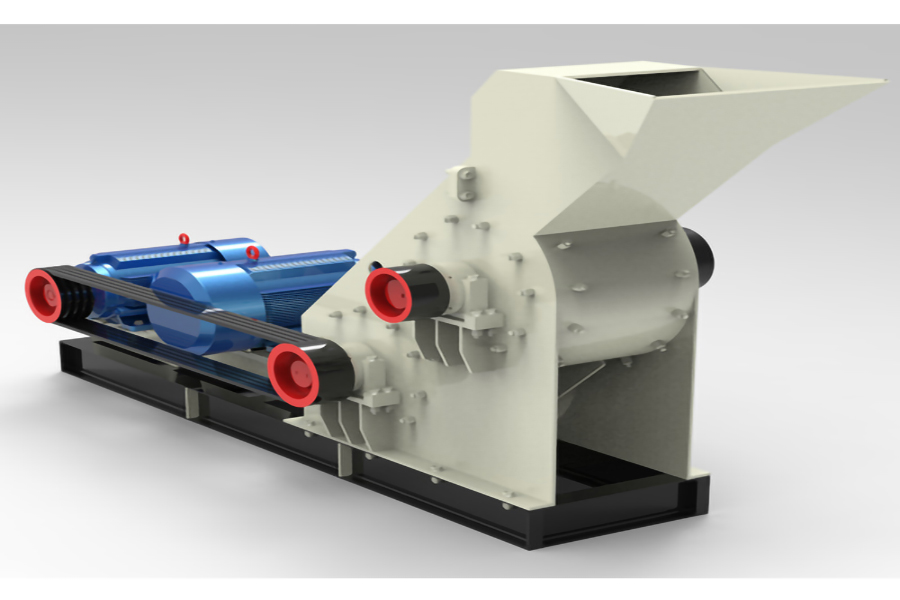

Hammer Mill for Sale in NPK Raw Materials Pretreatment

The hammer mill is a top sale npk fertilizer crusher used for large scale npk fertilizer production lines. It can process npk fertilizer production materials, coal, salt, white, gypsum, brick, limestone, or the like into fine powders with 10 to 20mm. How does it work to grind npk powders? When the hammer mill working, its motor drives the rotor to rotate at a high speed. Then, the npk production material will enters the crusher cavity evenly. With the high-speed rotating hammer impacts, shears and tears the material, fine npk powders will be out of the hammer mill.

At the same time, the gravity of the material itself causes the material to rush from the high-speed rotating hammer. Then the material will go through to the baffle plate and screen bar in the frame. In this process, if the material larger than the size of the screen hole, it will be blocked on the screen plate. Then, large sizes materials will continue to be crushed. It is hit and ground by a hammer until it is crushed to the desired output size. When fine npk powders made, it will be discharge out through the sieve plate. This machine is the best crushed product in the production of large-scale organic compound npk fertilizers.

Why choose the hammer crusher for your npk compound fertilizer production business?

Advanced structure: the bearing boxes of the hammer mill are all made of cast steel, and each shaft box is fixed with four screws.

Higher working efficiency: hammer mill has the characteristics of large crushing ratio, high efficiency and strong applicability. There is no invalid wear of the hammer head.

Powder outputs are uniform and fine. Hammer mill equipment adopts upper and lower two-stage rotors to crush, so that the crushed materials are more uniform and finer.

Fertilizer Hammer Crusher for Sale Technical Specifications

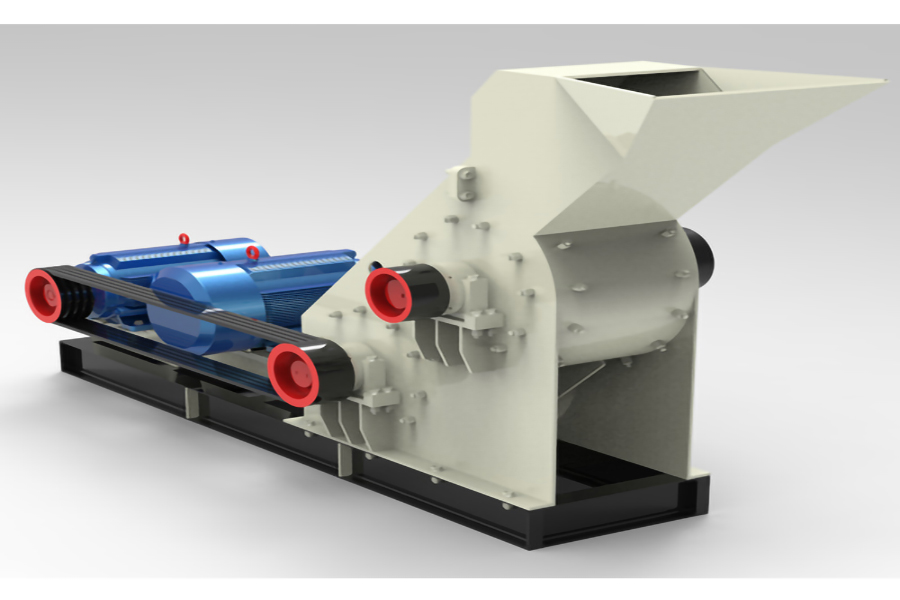

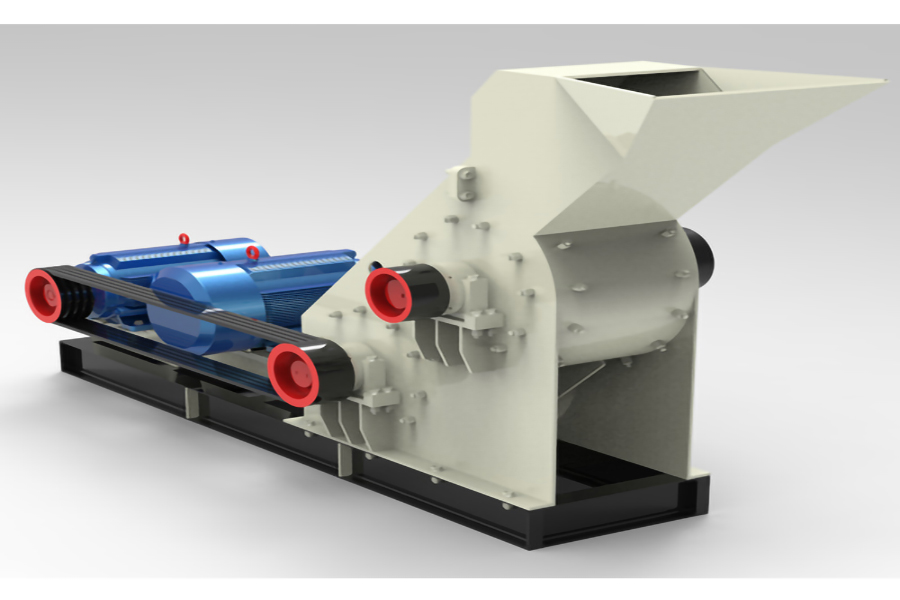

Top sale chain crusher in npk manufacturing process

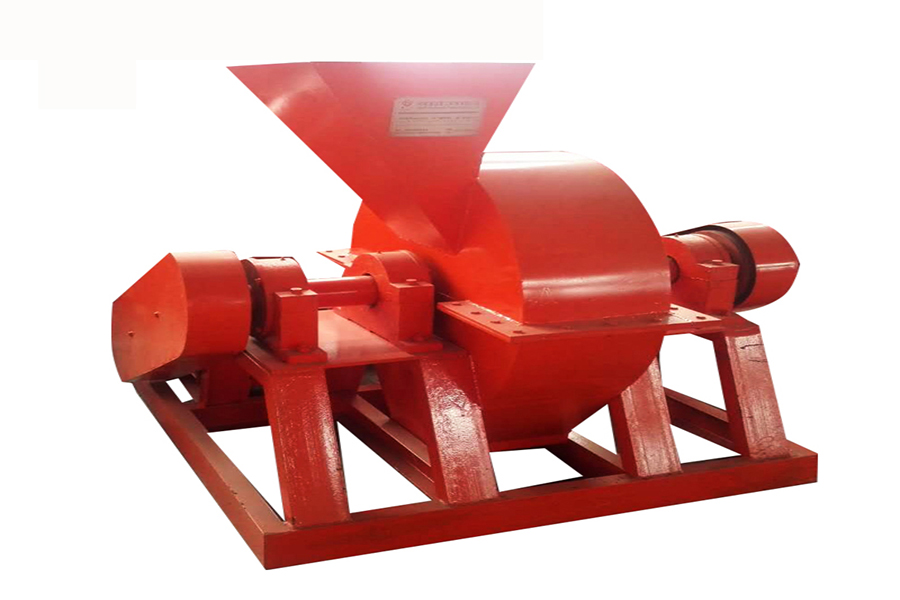

The chain crusher is divided into two types: vertical chain crusher and horizontal types. Vertical chain crusher has single rotor, while the horizontal chain mill has double rotors. It is suitable for crushing of block in compound npk fertilizer production. To grind returning materials in npk fertilizer production, it will be the best choice for most fertilizer npk manufacturing factories.

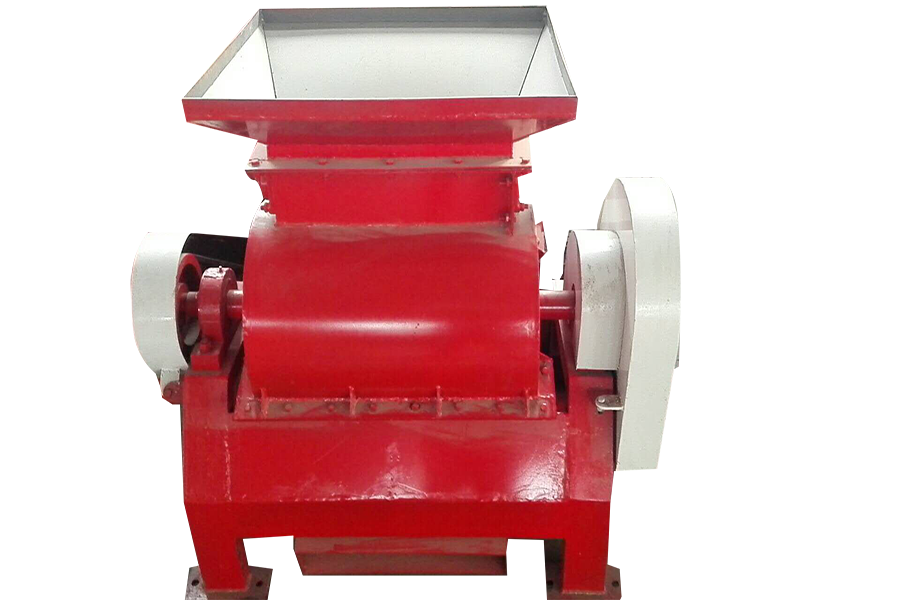

Cage npk crusher for sale used in npk fertilizer plants

Cage crusher is a medium-sized horizontal cage bars fertilizer grinder for compound fertilizer npk production. Designed by impact breaking technology, its two sets of cage bars inside and outside, can rotates in opposite direction with high speed. Then the npk material is crushed by the impact of the cage bar when through the two sets of cages. Outputs of powders has maximum capacities 10t per hour which is the ideal crushing equipment for npk compound fertilizer crushing.

Technical data cage mill in npk plants

Urea Crusher for NPK Fertilizer Manufacturing Line

NPK materials, like urea, need grind into fine powders for quality npk compound fertilizer granulation. To meet customers, this requirement on fertilizer npk powder making process, we develop the urea grinder for our customers npk plant. This type of urea crusher mainly used to grind and cutting material with the gap between the roller and the concave plate. The clearance size determines the degree of material crushing, and the drum speed and diameter can be adjustable.

Inquiry now for a best suitable fertilizer crusher for your npk fertilizer production line

Among the different types of fertilizer production crushers, how to choose a best one for your npk manufacturing business? What’s the price and cost of the crushers meet your requirements budgets? How do you choose based on your target npk fertilizer production business? Inquiry now to get all solutions in one packaging.