Coating Drum for Sale

-

- Production Capacity:2530 cubic meters per hour

- Voltage:220V/380V or Customized

- Dimension(L*W*H):3210mm*5270mm*3890mm

- Weight:10000 KG

- Reducer Model:ZQ350

- Motor Power:5.5(kw)

- Installation Angle:2-3(Degree)

- Rotary Speed:11 (r/min)

- Certification:CE,ISO9001

Get Price Now!

Description

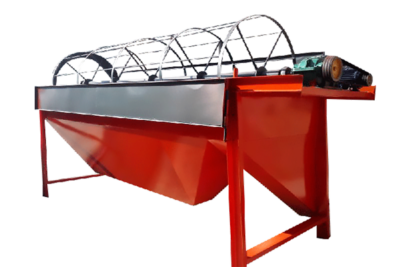

Coating Drum Machine for Sale in Compound NPK Fertilizer Production

Coating drum for sale in our factory is suitable for different types of fertilizer plants in the coating process. The rotary drum coating equipment can coat npk granules at large scale. It mainly includes four key components: the screw conveyor, mixer tank, oil pump and the driving engine. For powder dusting or liquid coating process in npk production, it is the key equipment. The coater drum manufactured from our factory are in lined with polypropylene or acid-resistant stainless steel which can let you use it for a long time. According different working processes in mixed fertilizer production, you can use different materials to make coated fertilizer with the rotary drum. As for the pellets fertilizer coating machine price, we will provide you best factory price based on your production capacity requirements.

Why use coating drum for you npk plant?

When making npk granules, there are different reasons to use the coating drum machine for your fertilizer production plant. The first one is the fertilizer itself requirements. The second one is for long time storing and distant transportation. The third one is to meet the fertilizer application requirements.

Coating for additional nutrient in the npk drum coating process

In the npk fertilizer production line, sometimes, especially when producing specialized npk compound fertilizers, it needs additional nutrients for the plants. In the fertilizer batching process, it may lead to nutrient loss, thus it needs to coat additional nutrients, in the drum coating process, especially the micro-nutrients.

Rotary coating to prevent npk fertilizer caking

In the npk granulation process, since most types are wet granulation technology. Even after the drying and cooling process, it may also occur caking when store or transport the fertilizer granules. Thus, it needs a granular coater drum machine using song dry powders coat on the npk granules surface to prevent caking.

Buy a rotary coater to make easy-applicable fertilizers

When fertilizer the npk granules in the farm, some plants need it take effects fast, while others not. To meet slow-release fertilizer requirements, it needs coat inhibitors to the final npk products. Or coating with catalysts to make it more water-soluble.

Rotary drum pellets fertilizer coating machine working principle

How to coat npk granules with the rotary drum coating machine? Its working principle is quite simple since its compact structural design. After the drum screening process, qualified npk pellets will moves into the next drum coating process by the belt conveyor. When the finished granules npk evenly flow into the rotating coating machine. They will keep rolling in the coating drum. Then, the prepared oily mixed coating agent will be sprayed on the surface of the compound fertilizer granules by means of compressed air and a special nozzle. Finally, the surface of the compound fertilizer particles will be coated with a uniform protective film. By this npk coating process, which effectively prevents the salting-out and moisture absorption of the fertilizer surface.

Technical performance for the drum coater

As a professional fertilizer production equipment manufacturer, we are always devoting ourselves in the npk coating drum machine researching and development. There are mainly fine key technical design highlights when we make the drum granular coating equipment:

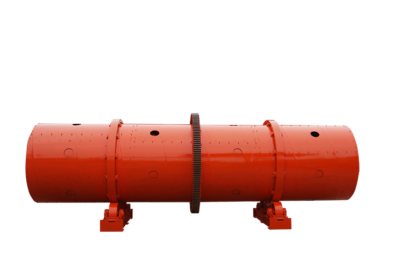

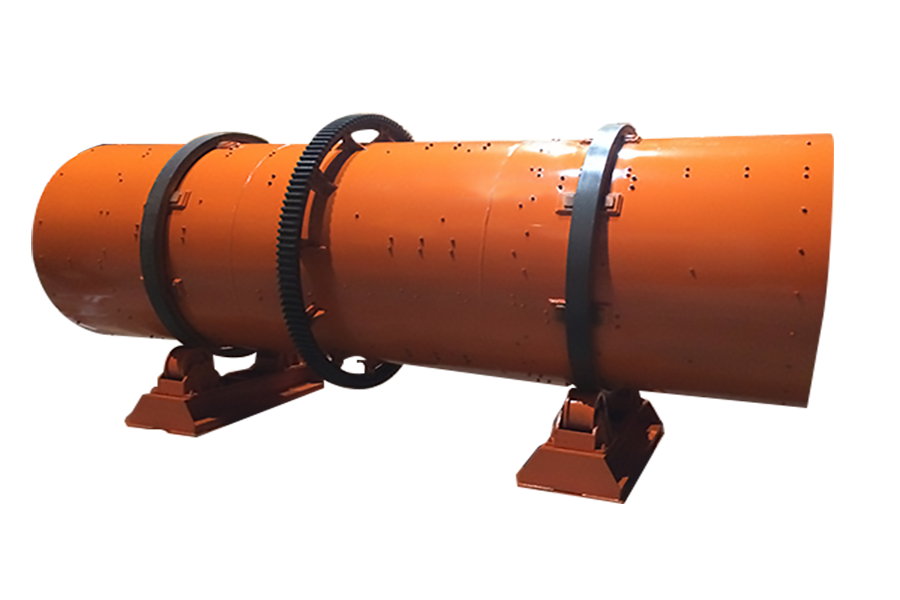

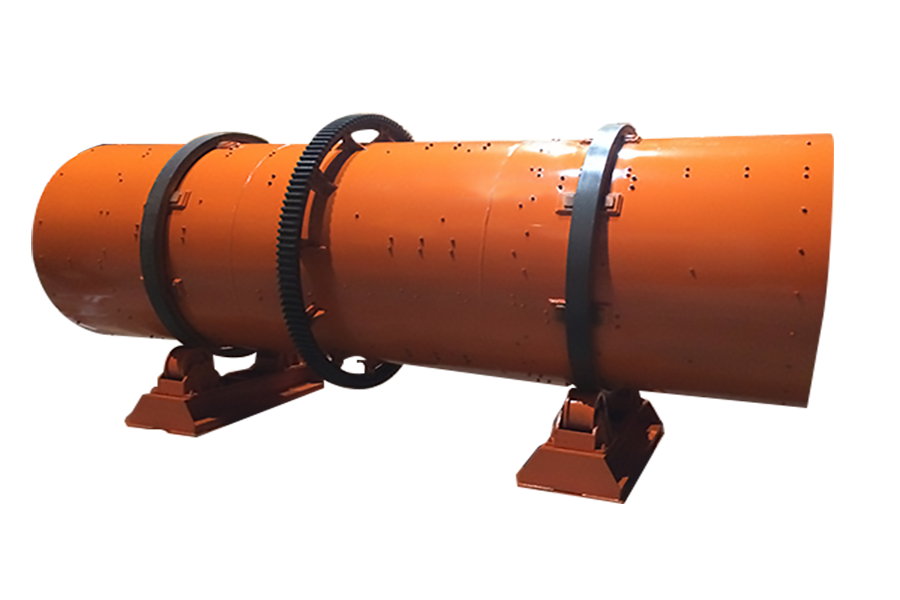

- Bracket part: The entire rotating part of the coating machine body is supported by the bracket, and the force is large. Therefore, the supporting parts of the machine drum coater are all welded with medium carbon steel plates and channel steel. All the materials and technology, we use have passed strict quality control and special process requirements. Meanwhile, it can also meet the requirements on the npk drum coating process. In addition to this, the more important thing is the supporting roller fixed on the shelf. Considering that it will have a large friction with the rolling belt of the body, our factory specially selects high-quality anti-corrosion and wear-resistant materials, which greatly improves the service life of the drum pellets coating machine. The frame also adopts casting integrated technology. In addition, there are hoisting hooks at the four corners of the supporting wheel frame, which is convenient for loading, unloading and transportation.

- Transmission part: The transmission part of the whole granulator coating drum is particularly important, and the work of the whole machine is based on this. The transmission frame is welded with high-quality channel steel. The main motor and reducer installed on the transmission frame are ISO products with reliable performance and reliable quality.

- Large ring gear: fixed on the machine body, meshing with the transmission pinion, and driving the machine body to work in the opposite direction. It adopts high-tech wear-resistant materials to make the machine last longer.

- Rolling belt: fixed on both sides of the body to support the whole body.

- Body part: The most important part of the whole coating machine is the body part, which is welded with high-quality medium carbon steel plates.

Where can you use the granules rotary drum coater?

For the ural granules coating: you can buy a drum coating machine for your granules fertilizer plants. After coating some hydrophobic material, it will make decrease the dissolution rate when application.

For complex npk granules blending plants: in this kind of fertilizer blending plant, customers always use Citric acid soluble calcium magnesium phosphate fertilizer as the coating layer. It will depend on the requirements of the fertilizer plants, then it will make the coated fertilizer have some functions for certain crops.

Materials used in npk drum fertilizer coating process?

As the above mentioned, you can use different types of coating agents baed on your certain requirements. Usually, customers can use the Sulfur, Phosphate, Paraffin, Bitumen as coating materials for your npk fertilizer production plant. Or the Citric acid soluble calcium magnesium phosphate fertilizers a for nutrients applications. While, for functional applications, you can use potash fertilizers, Micro fertilizers, Chelating agents, Pesticides, etc., for functional npk compound fertilizer production.

Pellet drum coating machine price

Different types of drum coating machines are different in costs and prices. The large the production capacity of the coating drum, the price will be higher. As a both a manufacturer and supplier, all types of granulation drum coater we sell for you are at factory price. There are 1t to 30t capacity per hour drum coating machines available for your npk plant, the following technical parameters just for your reference, for more detailed info, on the drum coater price in your npk production, welcome inquire us now for professional quotations.