Rotary Drum Churning Granulator

- Output (kg/h): 15000

- Voltage: 380v

- Power (kW): 18.5

- Diameter: 2000mm

- Length: 8000mm

- Installation Angle: 2-5°

- Motor Power: 18.5kw

- Rotary Speed: 11r/min

- Raw material: Animal Manure, Organic Compound Fertilizers

Get Price Now!

Description

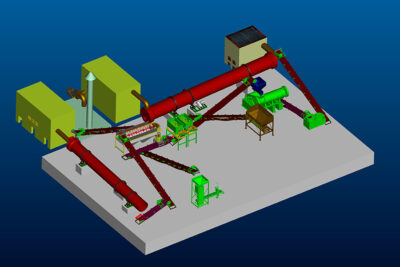

Rotary Drum Churning Granulator is a fertilizer pellet machine that can make materials into specific shapes. The two in one rotary drum granulator is one of the key equipment’s in the compound fertilizer industry. It is suitable for cold and hot granulation and large-scale production of medium and low concentration compound fertilizers. The main working method is wet granulation of agglomerates. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder after humidity adjustment. Produce extrusion force to agglomerate into balls. The barrel of the machine is lined with rubber plate or acid-resistant stainless steel, which realizes automatic scar removal and tumor removal, and cancels the traditional scraper device.

The Rotary Drum Churning Granulator for Sale machine has the advantages of ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc. The wet tooth granulator uses the mechanical stirring force of high-speed rotation and the resulting aerodynamic force to make the fine powder material continuously realize the processes of mixing, granulation, spheroidization, and densification in the machine, so as to achieve the purpose of granulation. The combination of these two granulation methods makes the granulation rate higher, the granules more beautiful, and at the same time saves energy and quality.

How does the drum churning granulation machine work in the compound fertilizer production line?

Using high-speed rotation and mechanical stirring and the resulting aerodynamic force, the fine powder material can be continuously mixed, granulated, spheroidized, and densified in the machine, so as to achieve the purpose of granulation. The particle shape is spherical, the sphericity is greater than or equal to 0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is greater than or equal to 90%. The size of the particle diameter can be appropriately adjusted by the mixing amount of the material moisture and the spindle speed. Generally, the lower the mixing amount, the higher the rotational speed, the smaller the particles, and vice versa.

Two in one fertilizer granulation machine technical specifications

| Model | Name | Feed Particle Sizes | Moisture | Granular Sizes (mm) | Drum Thickness (mm) | Installation Angel | Capacity (t/h) | Power (kw) | Dimension (mm) |

| ZJZ-1660 | 1.6×6mTwo-in-one granulator with turning and stirring teeth | 50Mesh | 20%-40% | 2-6 | 12 | 2°-2.5° | 4-6 | 45+22 | 7500×2200×2250 |

Technical Features of the two in one fertilizer granulation machine

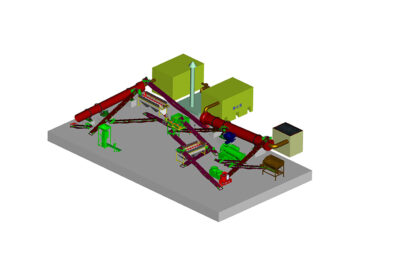

Rotary drum stirring teeth two-in-one granulator is a fertilizer production machine that can make materials into specific shapes. This machine is one of the key equipment in the compound fertilizer industry. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. Its main features are as follows:

- Compared with natural agglomeration granulation devices (such as rotary disc granulator, drum granulator), it has a concentrated particle size distribution and is easy to control;

- The pellets produced are spherical. High organic content, to achieve pure organic granulation;

- High efficiency, easier to meet the requirements of large-scale production;

- The spherical particles have no acute angle after granulation, so the pulverization rate is extremely low.

Why to buy this type of fertilizer granulator for your fertilizer plants?

This machine has the characteristics of beautiful appearance, simple operation, low energy consumption, long life, uniform drying, convenient maintenance, etc. It is the most advanced granulation equipment in China. This product is suitable for cold and hot granulation and high, medium and low concentration compound large-scale production of mixed fertilizer, the product is now all over the country. Its main features are as follows:

- Low investment, quick effect, good economic benefit and reliable performance;

- Small power, no three wastes, stable operation, convenient maintenance, reasonable process layout, advanced technology and low production cost;

- High ball strength, good appearance quality, corrosion resistance, wear resistance and low energy consumption;

- The cylinder is lined with a special rubber plate, which realizes automatic scar removal and tumor removal, and cancels the traditional scraping device.

Get a Free Quote with Detailed Price Lists, Inquiry Us Now