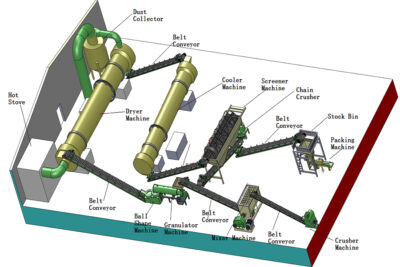

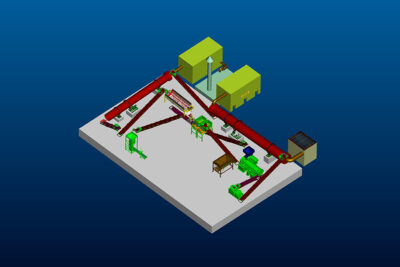

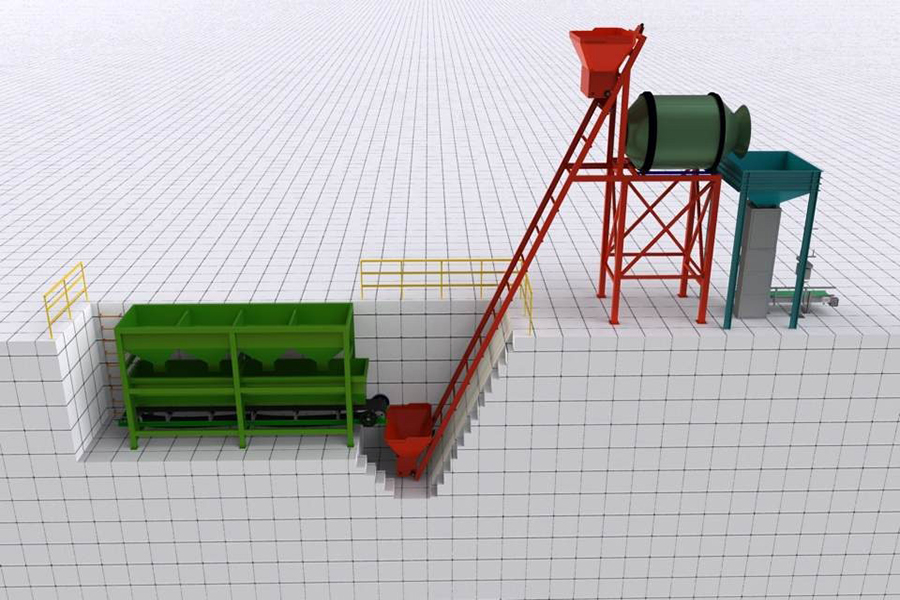

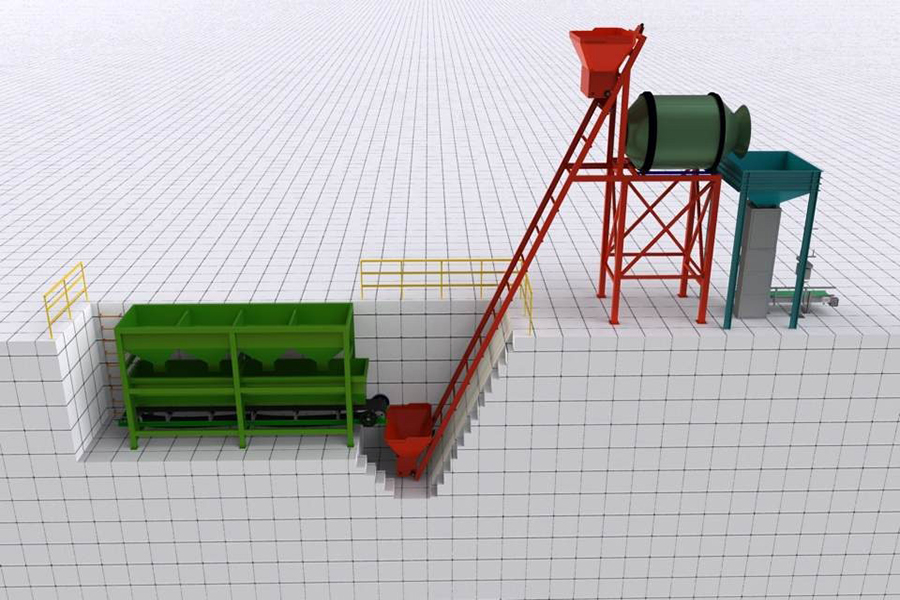

Bulk Blending Fertilizer Production Line for Sale

- Production Capacity: 10,000 to 200,000t Annually Organic NPK Fertilizer Production

- Turnkey Project Solutions:Provided

- Customized Services:Provided

- Installation:Provided

- Main Equipment: Blender, Conveyor, Packer, etc.

Get Price Now!

Description

A bulk compound fertilizer is a dry blend of fertilizers containing two or more nutrients. Loose mixing is a simple mixing process, the purpose is to make various nutrients mixed and applied at the same time, and can meet the needs of crops. Bulk compound fertilizer is not necessarily a commodity, it can be a fertilizing mixture; it is not necessarily produced by factories, but can be directly mixed and used by farmers. According to recent reports, most of the total fertilizer used by farmers in the United States today is applied as a loose mix.

List of the most commonly used basic fertilizers purchased by the mixed fertilizer factory for the preparation of mixed fertilizers.

In Table 2-47. The most widely used source of phosphorus is granular diammonium phosphate, approximately 95% of composting plants use this fertilizer. Diammonium phosphate is indeed an ideal compound fertilizer. It was developed in the early 1960s, and it played a great role in the promotion of bulk fertilizers.

Table 2-47 Basic fertilizers for Bulk Blend Fertilizer Production

| Basic Fertilizer Types | Main Contents(N-P2O5-K2O) |

|---|---|

| Ammonium nitrate | 34-0-0 |

| Urea | 46-0-0 |

| Ammonium sulfate | 21-0-0 |

| Diammonium phosphate | 18-46-0 |

| Monoammonium Phosphate | 11-52-0 |

| Heavy calcium | 0-46-0 |

| Calcium calcium | 0-20-0 |

| Potassium chloride | 0-0-60 |

The advantageous characteristics of diammonium phosphate are its good storage and transportation properties, and its low nitrogen and high phosphorus components are suitable for plants growth.

It is suitable, and it is almost miscible with other mixed fertilizers. While, monoammonium phosphate has the same desirable properties, but not yet available in large quantities in granular form.

Granular heavy calcium. It has been a commonly used source of phosphorus, but it has disadvantages:

(1) its crop nutrient content is higher than that of phosphate diphosphate. Ammonium is low (diammonium phosphate is 64);

(2) it cannot be used with urea, a commonly used nitrogen source for complete mix. Urea is the most widely used nitrogen source in composting, with 66% of plants use. In the early 1970s, the emergence of urea agglomeration technology greatly promoted.

The use of urea in composting, because the conveying and mixing properties of the agglomerated product much superior to the urea prilling tower in the past. About 20% of factories use another type. The nitrogen fertilizer, ammonium sulphate, is used due to its low nitrogen content (20% nitrogen) and granular ammonium sulphate supply is limited due to insufficient supply. But it has the advantage of soluble sulfate higher levels, which may be beneficial for crops in certain regions. Potassium chloride has always been the primary source of potassium used in composting, which is easy to obtain the desired aggregate size.

And has good storage and transportation performance. The main bulk mix at the compost plant in 1980. The varieties of fertilizers are 9-23-30, 6-24-24, 10-10-10, 19-19-19, 17-17-17,8-32-16, 10-20-20, 0-26-26, 6-15-50 and 10-26-26. Some of which is a typical formulation of the product is shown in Table 2-48. In order to improve fertilizer efficiency, some other materials are being dried.

Table 2-48 Typical formulations for bulk blend fertilizer manufacturing process

| Mixed base fertilizer | 17-17-17 | Basic Fertilizer Required to Make 1t Mixed Fertilizer, lb | |||

|---|---|---|---|---|---|

| 19-19-19 | 9-23-30 | 8-32-16 | 0-26-26 | ||

| Ammonium nitrate | 34-0-0 620 | ____ | ____ | ____ | ____ |

| Urea | 46-0-0 ---- | 513 | ____ | ____ | |

| Diammonium phosphate | 18-46-0 752 | 842 | 1000 | 924(1) | ____ |

| Heavy calcium | 0-46-0 ---- | ____ | ____ | 522(2) | 1132 |

| potassium chloride | 0-0-60 577 | 645 | 1000 | 544 | 868 |

| Filler (Granular Limestone) | 0-0-0 51 | ____ | ____ | ____ | ____ |

Note:

(1) When stored, a chemical reaction may occur between diammonium and tricalcium.

(2)1lb=0.453kg

It is also often simply added to the bulk mix during the npk mixing process. Other materials that are often added are mesonutrients, such as sulfur and magnesium; micronutrients, such as compounds of zinc, boron, copper, and manganese; herbicides; anti-caking additives, and seeds.

For the production of bulk compound fertilizer, directly according to the formulated formula, weigh and add them together for mixing. The principle of ingredients and the range of material selection can refer to the production of granular compound fertilizer.