Crawler Windrow Turner

- Core Components: PLC

- Voltage: 380v/220v

- Dimension(L*W*H): 3000*1850*1780MM

- Usage: Turning Mixing Organic Compost

- Raw Material: Organic waste, manure

- Function: Compost Turner Mixing Machine

- Working Width: 3-30m

- Working height: 1500-2000mm

- Working speed: 6-18m/min

- Capacity: 400-1200 cubi meters/h

Get Price Now!

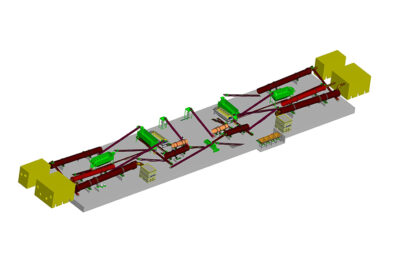

Description

The organic fertilizer crawler windrow compost turner for sale belongs to the ground stacking and fermentation mode or the windrow composting technology, which is a fertilizer-making machine that saves civil construction and human resources at present. The material needs to be piled up into long strips or windrows, and the material is stirred and crushed by the windrow turning machine regularly, and the organic matter is decomposed under aerobic conditions. It has the function of crushing, which greatly saves time and labor, greatly improves the production efficiency and product quality of the organic fertilizer plant, and greatly reduces the cost.

When the windrow turner is working, it can effectively mix sludge, viscous chicken manure and other materials with bacteria and straw powder evenly. It creates a better aerobic environment for material fermentation. Not only is it much faster than deep groove fermentation, but it also effectively prevents the production of harmful and malodorous gases such as hydrogen sulfide, amine gas, and indole during the fermentation process, meeting environmental protection requirements.

Technical Advantages for you to buy a windrow turner machine for your commercial composting plant

- Easier operation, eliminating the hydraulic direction type, saving space, labor, diesel oil, shortening the working time, and advancing the fermentation cycle.

- The front hydraulic push plate is installed, which eliminates the need for manual time-consuming for the whole stack.

- This product’s turning clutch adopts soft start, which is more stable and durable.

- The drum is hydraulically raised and lowered, and the cab can be optionally equipped with air conditioning.

Crawler type self-propelled windrow compost equipment working principle

(1) Part of the main output of the diesel engine power drives the turning drum through the pulley deceleration drive; the other part of the power is output through the diesel engine sub-power box to drive the hydraulic pump. Hydraulic pump, actuator cylinder lifting cylinder, diesel engine clutch cylinder and traveling crawler drive motor form a hydraulic circuit system to realize the lifting and lowering of the throwing drum, the main driving force of the diesel engine to drive the drum to work and stop, and the self-propelled equipment.

(2) When working, the operator in the cab starts the engine, and by controlling the hydraulic valve group, the following functional commands can be realized: operate the valve stem of the “walking motor” to make the machine move forward, backward and turn left and right; operate the “rolling and lifting cylinder” the valve stem enables the drum to be placed in the stack at a suitable height from the ground, and the drum can be lifted to a certain height, which is convenient for the machine to move quickly and transfer the working site. Operate the “engine clutch cylinder” valve stem to realize the drum rotation and stop; valve stem to realize the switch between the high and low speed of the machine.

(3) The turning and throwing drum is composed of two left and right reverse spiral sections and a middle straight section of throwing teeth. The rotating spiral drum stacks the triangular strips of materials

It is gathered in the middle, and at the same time, the material is thrown backwards with the rotation of the drum, so that the top material and the inner material are fully mixed.

The material and oxygen are in full contact, and the hot air in the stack is exposed. So as to realize material mixing, ventilation, aeration, turning and throwing, to achieve the purpose of compost fermentation.

Technical structural design for the crawler type compost windrow turner for sale

- The power is 38-55KW vertical water-cooled diesel engine, with sufficient power, high efficiency and low fuel consumption.

- With the hydraulic power balance device, although the body is large, the steering is flexible, which is convenient for field operations.

- All using joystick operation, flexible and simple.

- The stacker is used to automatically adjust the four-wheel balance in the convex and concave site to improve the adaptability of the site.

- Hydraulically adjust the distance of the turning shaft from the ground. Prevent the turning shaft from hitting the ground.

- Equipped with cab.

- Optional air conditioner.

- Turners with more than 120 horsepower can be customized according to user requirements.

Raw materials we use in manufacturing you a high-quality windrow turning machine

- The whole vehicle adopts GB profiles, which is more solid as a whole;

- The whole car adopts laser cutting, and the production technology is advanced;

- Unique hydraulic power balance device;

- The drum part adopts seamless thick-walled steel pipe. Dynamic balance correction, stable operation;

- The bottom of the straddle is made of 304 high-quality stainless steel, which has stronger corrosion resistance and longer service life;

- Joystick operation, flexible steering;

- Weituo 116 hp water-cooled turbocharged engine.

How to operate the windrow crawler type compost turner machine?

The windrow compost turner crawler type is a field operation machine, and its operation and use method is different from that of ordinary vehicles. In order to ensure the correct, safe and efficient use of the compost equipment, please run the machine for 40 hours before the actual dumping operation (driving, reversing, turning, etc.). During the running-in period, it is strictly forbidden to turn over the pile.

The compost turner machine should be operated by a person who is qualified to drive a motor vehicle and has more than 40 hours of practical operating experience. (Recommendation: Drivers who have experience driving combine harvesters are candidates).

When operating the pile compost turner to carry out the pile turning operation, it should be operated in strict accordance with the operating regulations.

After 40 hours of running-in, please replace the gear oil in the reduction box, and check all the connection parts, pay special attention to the fastening bolts on each transmission shaft seat.

Check and tighten (the hood and the lower front panel of the cab should be opened. careful inspection). Warning!

Those who have no experience of driving a stacker for more than 40 hours are prohibited from turning over the stack to prevent damage to the stacker.

(1) Requirements before start-up

- Before starting the machine, check whether the machine is affected during transportation and whether all parts are fastened firmly.

- Check the electrical facilities, whether the circuit connection is in good condition and whether the insulation is reliable.

- Check whether the transmission belt is normal and moderate, whether there is serious wear and tear, and whether the tire pressure is normal.

- Please use diesel oil, oil and cooling water according to the diesel engine instruction manual. Check the oil level (between the marks on the dipstick) before starting the machine.

- Adjust the distance between the head of the shaft cutter and the ground. The distance between the head of the cutter body and the ground should be about 5cm.

(2) Start the starter

- When starting, separate the turning shaft;

- The engagement time of the starter ignition should not exceed 10 seconds, the continuous starting should not exceed three times, the interval between each two starting should be greater than 2 minutes, and the idling should be run for 10 minutes after starting.

- When the equipment is working, increase the throttle to about 2000 rpm, slowly release the clutch, and the turning shaft starts to rotate.

- Hang “1” to turn the pile. If the chimney of the diesel engine emits black smoke, it means that the material is overloaded. At this time, please depress the clutch. After the diesel speed returns to normal, loosen the clutch and continue to turn over the pile. warn!

Technical specifications for the crawler type windrow turner compost production machine

| Model | LFP2000 | LFP2300 | LFP2600 | LFP3200 |

| Width(m) | 2.0 | 2.3 | 2.6 | 3.2 |

| Height(m) | 0.5-0.9 | 0.6-1.1 | 1.3 | 1.5 |

| engine speed/min | 2200 | 1800 | 1800 | 1800 |

| Turning diameter mm | 570 | 570 | 735 | 735 |

| Power | 32 Horsepower water-cooled electric start | 85 Horsepower water-cooled electric start | 108 Horsepower water-cooled electric start | 150 Horsepower water-cooled electric start |

| Processing capacity m3/hour | 400-500 | 500-700 | 800-1000 | 900-1500 |

| Size (mm) | 2150×2600×2350 | 2150×2900×2400 | 2550×3840×2980 | 2360×3800×3100 |