In-vessel Composting Equipment

- Core Components: PLC, Engine, Motor, Pressure vessel, Gear, Pump

- Production Capacity: 8-12m3/d

- Place of Origin: Henan, China

- Voltage: 380V

- Weight: 35 KG

- Dimension(L*W*H): 6000mm*6000mm*7900mm

- Features: Automatic

- After-sales Service Provided: Field installation, commissioning and training

Get Price Now!

Description

Our company independently developed the in-vessel composting machine, which mainly conducts high-temperature aerobic fermentation of livestock and poultry manure, kitchen waste, domestic sludge and other wastes, and uses the activity of microorganisms to ferment the waste in the composter. The decomposed organic matter is bio decomposed, and the decomposed organic matter can be made into organic fertilizer, which is an effective measure to turn waste into treasure and improve environmental quality, thus realizing the recycling and reuse of resources.

As one of the main products of our factory, the organic fertilizer fermentation tank works on the principle of applying biological fermentation technology to benefit human life, namely livestock and poultry manure, kitchen waste, domestic sludge, etc. After the waste is mixed evenly in a certain proportion, the moisture content of the mixture is sent to the fermentation tank after reaching the design requirements.

During this period, the intelligent high-temperature aerobic sludge treatment equipment controls the temperature between 55 and 60 °C through ventilation, oxygenation, stirring, etc., to achieve the optimum temperature for sludge fermentation treatment. A large number of pathogenic bacteria and parasites in the body, and at the same time, the deodorization system is used to carry out biological odor of the discharged gas, so as to achieve the purpose of harmless sludge treatment.

Organic Fertilizer Fermentation Tank High Temperature Aerobic Fermentation Process

The operator adjusts the moisture, oxygen content and temperature of the raw materials in the outside to provide active conditions for the itchy bacteria to carry out high-temperature aerobic fermentation technology. The organic matter is decomposed by biology, so as to achieve an integrated sludge treatment equipment that is harmless, stabilized, reduced, and utilized as a resource. The product obtained after high-temperature aerobic fermentation of sludge can be used for soil improvement, landscaping, landfill cover soil, etc. It features low energy consumption and low operating cost. In addition, the equipment covers a small area and has a high degree of automation. One person can control the organic fertilizer in-vessel composter to complete the fermentation process. Greatly reduce the input of human and material resources in the production process, and greatly reduce the compost production cost.

Features of the organic fertilizer fermentation tank

The vertical closed tank structure saves the floor space and better reduces the area requirements for equipment installation.

The second feature of the organic fertilizer fermentation compost machine is that it is driven by hydraulic pressure and has a large thrust, which can ensure the full-load operation of the decomposed material in the tank, ensuring operation and low maintenance cost.

The third feature of the compost fermenter: The inner part of the tank is made of polyurethane as the insulation layer, which is less affected by the outside world and ensures fermentation throughout the year.

Features 4 of the organic fertilizer fermentation machine: The treatment process is completely closed and does not produce secondary pollution;

Biological deodorization is adopted, and the exhaust gas is discharged up to the standard during the treatment process;

The organic manure fermentation tank features five: the operation is fully automated, and the unmanned operating system can be realized.

The in-vessel composter features six: it avoids the slow rise of the composting temperature of the traditional composting fermentation technology, the low composting temperature, and the short duration of the high temperature, which leads to a long composting production cycle, and the removal effect of pathogenic bacteria and heavy metals is difficult to reach the standard of land use. During the fermentation process, there are a series of problems such as serious odor pollution and poor sanitary conditions.

How to make compost fast with the in-vessel composter machine?

- The equipment occupies a small area, can be installed outdoors, and does not require a workshop. It is a mobile processing plant, which solves the high cost of plant construction, long-distance transportation and centralized processing.

- Fast fermentation, organic fertilizer can be produced within 24 hours.

- Sealed treatment, deodorization in the tank, breaking through the traditional composting method and realizing industrialization of production.

- Good thermal insulation, not limited by seasonal cold.

- The output is large and the added value is high. The processing capacity can be increased according to the needs, and multiple sets can be installed.

- Low energy consumption, the electricity consumption per ton of garbage is only more than 40 kWh.

- High temperature and aerobic bacteria breed fast, and the formed beneficial flora can kill harmful bacteria in raw materials.

- Standard operation, automation, mechanization, less labor, simple operation and management, input of raw materials such as livestock and poultry manure, automatic production of organic fertilizer, easy to learn and easy to operate.

- Three-layer structure, good mechanical material, solve the problem of strong acid and alkali corrosion, long service life, can be used for more than 10 years.

- The finished organic fertilizer mainly includes nitrogen fixation, phosphorus solution, potassium solution, yeast, fungus and a variety of flora that are beneficial to plants.

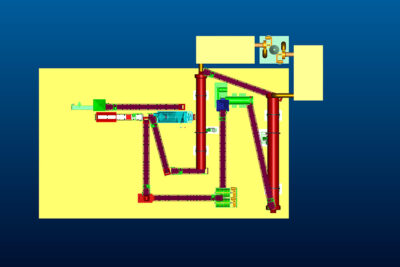

Structural design of the vessel-closed fermentation tank

- The tank body is closed: the tank body is fully enclosed, and the exhaust gas produced by fermentation is discharged out of the tank after passing through the exhaust gas treatment system to eliminate secondary pollution.

- Drive design: Hydraulic drive is adopted, with large thrust, which can ensure the full-load operation of the decomposed heat in the tank, ensure safe and stable operation, and low maintenance costs.

- Insulation treatment: The inner part of the tank is made of polyurethane as an insulation layer, which is less affected by the outside world and ensures fermentation throughout the year.

- Long service life: all parts in contact with feces are made of 304 stainless steel, which is anti-corrosion and has a long service life.

- Electrical control: It adopts PLC chip automatic and manual control system, which is convenient for operation and control.

Tank-type organic aerobic fermentation tank is suitable for organic wastes such as livestock and poultry manure, dead livestock and poultry, kitchen waste, urban sludge and so on.

Technical specifications for the in-vessel composting equipment

| Model | Heating Power(kw) | Mixing Power(kw) | Reducer Model | Mixing Speed(r/min) | Ddimensions(mm) |

| FT-5 | 4*6 | 7.5 | BLED74-289-7.5 | 3 | 2200*2200*5300 |

| FT-10 | 4*6 | 11 | BLED85-439-11 | 3 | 2400*2400*6900 |

| FT-20 | 8*6 | 18.5 | BLED95-391-18.5 | 3 | 3700*3700*8500 |

| FT-90 | 46 | 26.5 | XWD4-29-3-4 | 8-10 | 5000*5000*10000 |