Poultry Manure Plant

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Poultry Manure

- Industry Serviced: Poultry Farm Waste Management, Chicken Farm Litter Disposal

- Complete Set of Machine:Provided

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

Human, livestock and poultry manure is rich in organic fertilizers and also contains a certain amount of plant growth nutrients such as nitrogen, phosphorus and potassium. Human, livestock and poultry manure has been widely used in crops as farm manure since ancient times, and has the advantages of long fertilizer efficiency and so on. With the development of the breeding industry, mechanically arranging poultry has become the main body of today’s breeding industry, and the centralized use of livestock and poultry manure has become an urgent problem that needs to be solved, which also provides excellent raw materials for the production of organic compound fertilizers. The composition of various human, livestock and poultry manures is shown in Table 6-17.

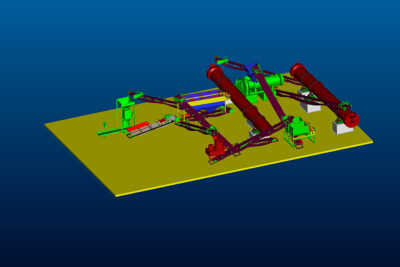

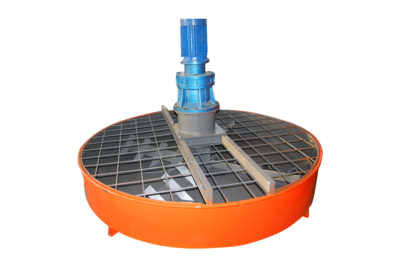

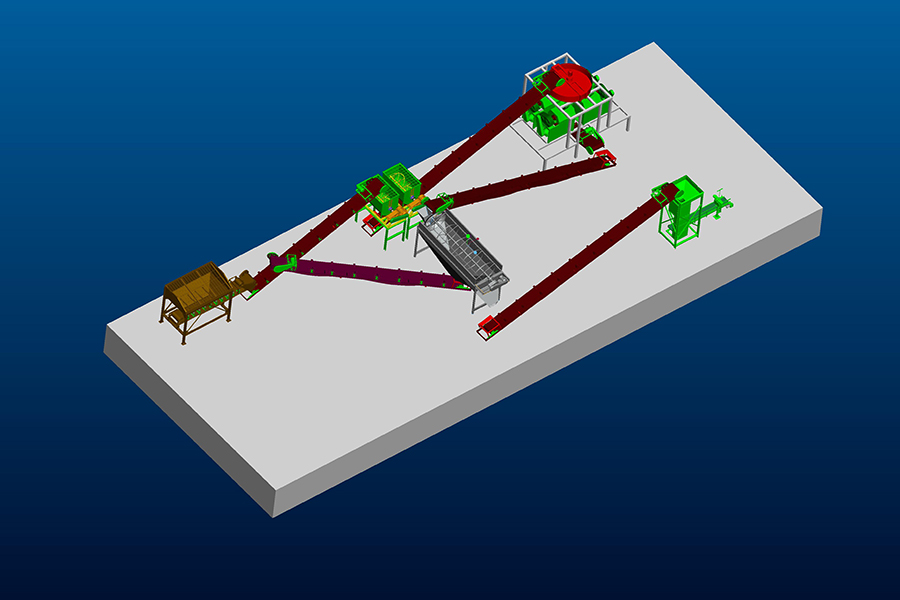

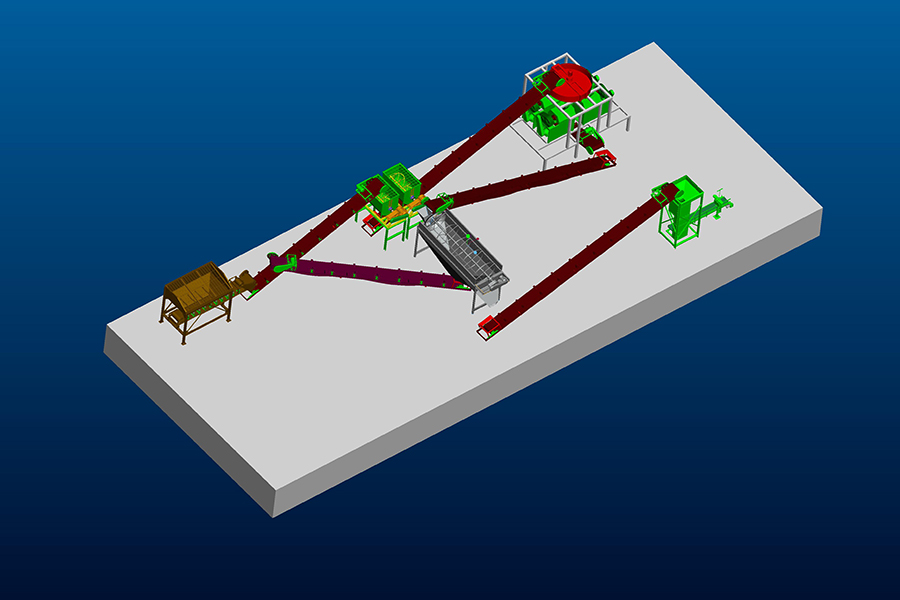

First, the human, animal and poultry manure is mixed and stirred in a certain proportion, and then filtered.

Non-fermentable sundries such as chicken feathers are filtered out, and then enter the digester, using anaerobic microorganisms substances, to ripen feces and to kill parasite eggs, bacteria and viruses so as not to produce unwanted.

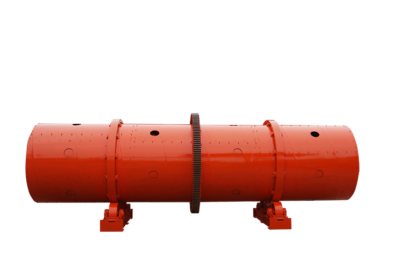

Good effect, while producing biogas as fuel. Aged feces are concentrated and dehydration to separate out 30% to 40% of the water. Then send it to the rotary drum dryer to dry.

The manure is crushed and then added with N, P and K basic fertilizers to produce compound fertilizers.

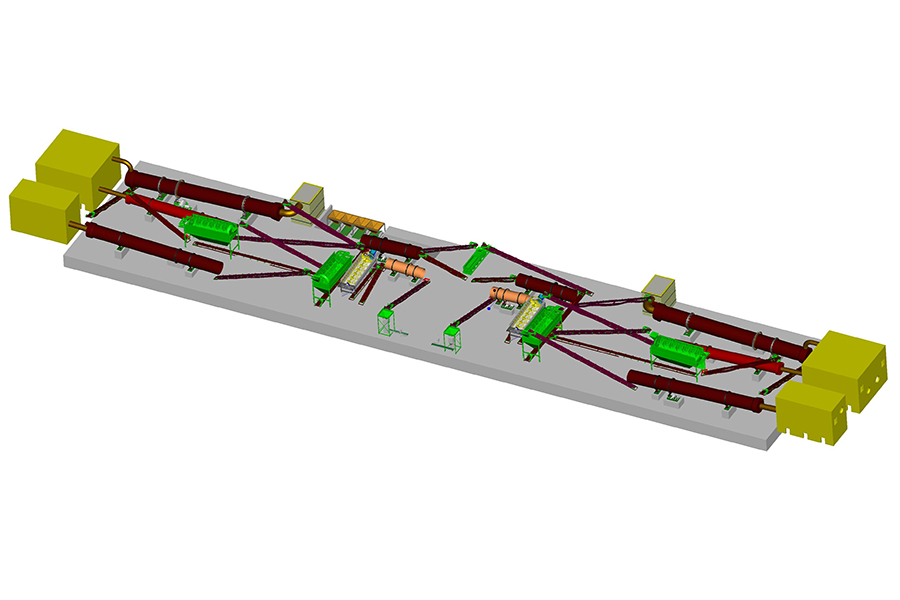

The separated and fermented waste liquid has high biochemical oxygen demand (BOD) and chemical oxygen demand (COD), and also contains certain nutrients, which can be used to irrigate farmland and make full use of its nutrients and trace elements. If the irrigation cannot be used up, the method of oxidation pond can be used to discharge or recycle the water. The second method is to directly dry with hot air, add an appropriate amount of dispersant to the poultry manure, and after stirring evenly, send it to the rotary manure dryer machine with a belt conveyor or bucket elevator for drying. The manure is in countercurrent contact, and the temperature of the drying kiln population is relatively high, while the outlet temperature is relatively low, generally not exceeding 80 °C, to ensure that nutrients are not lost, but the eggs can be killed, and the drying rate of moisture can reach 80%.

The operation index of the drying kiln can be determined with reference to the ternary compound fertilizer drying equipment. In addition, there is also a method for treating poultry manure, which is aerobic fermentation. The fermentation process adopts ventilation at the bottom of the fermentation tank to make the poultry manure heat up and ferment. The nitrogen, phosphorus and potassium content of poultry manure and the release of other amino acids were related to time, temperature and pH value during the fermentation process.

The main production conditions are: the water content of the feces after fermentation is 90%

Fecal water content < 50% after dehydration

Water content of feces after concentration: 50% ~ 70%

Dry inlet temperature (feces): 350℃

Dry outlet temperature (feces): 120℃

The other conditions are the same as the production of ternary compound fertilizer with ordinary calcium.

In addition to the above-mentioned methods, livestock manure can also be used as a raw material, and an appropriate amount of catalytic enzymes can be added to convert the various nutrients in the livestock manure into nutrients that can be absorbed by plants. The reaction is carried out in a mechanical reactor. After the reaction is completed, auxiliary agents such as alum or talc are added to remove the odor in the reactant. In order to obtain a pure product with high nutrient content, additives such as synergists and gelling agents should be added, followed by dehydration, drying and pulverization to obtain the finished product. The finished product produced by this method can increase the yield by more than 10%, and can also enhance the disease prevention, disease resistance and drought resistance of crops.

Taking chicken manure as the basic raw material, adding silica sol, silicon dioxide and concentrated sulfuric acid, through a suitable process, an instant and efficient organic fertilizer is made. The process is:

- Raw materials

Chicken manure can be used by collecting chicken and duck manure from chicken farms. It is the basic raw material of this product.

Silica sol, also known as silicic acid sol, is a colloidal solution of polymolecular polymers and is used as a deodorant.

Silica, also known as silica, is white or colorless and is used as a dispersant. Quartz, quartz sand, turpentine, etc. can also be used as dispersants, and the particle size is 200 meshes.

Sulfuric acid 60% ~ 98% H2SO4.

- Recipe

The formula is shown in Table 6-20.

- Preparation method

First prepare active silica sol, use electrical energy method, and use iron for electrodes. Apply 100V voltage to the two poles first, after 2.5min, energize 450mA, the pH value of the silica sol solution is 2.46; after 5min, turn on 475mA, the pH value of the silica sol solution is 2.16; after 8min, the electricity is 525mA, and the pH value of the silica sol solution The value is 2.11; after 11min, the energization amount increases to 530mA, and the pH value of the silica sol solution is 2.04. After that, the amount of energization and pH value did not change, and the applied voltage was stopped at 15 minutes to obtain an active silicic acid sol containing SiO2 5% to 25%. The prepared silica sol is used as an active agent, and various raw materials are mixed and heated to 70-80° C. according to the formula, and the reaction can be performed for 30-60 minutes.