Vertical Shredder for Sale

- Motor Type: AC Motor

- Capacity(t/h): 10-190t/h

- Dimension(L*W*H): 3100*1900*2200 mm

- Input size: <180 mm

- Output size: <3-5 60-90% mm

- After-sales Service Provided: Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, No after-sales service, Engineers available to service machinery overseas

Get Price Now!

Description

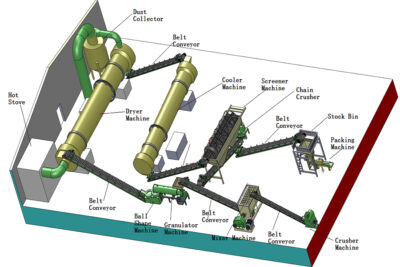

Vertical Shredder machine in our factory can crush npk fertilizer ingredients into fine powders. The vertical pulverizer is a kind of non-sieve, adjustable fine fertilizer crushing equipment which is optimized and designed on the basis of absorbing advanced fine crushing equipment at home and abroad.

Vertical Shredder for NPK Powder Making

As for the application fields, it can be widely used in one of the mainstream equipment of mineral processing equipment. While for the applicable materials, it can be used for final crushing of various materials such as limestone, cement clinker, mixture, gypsum, coal gangue, slag, copper ore, iron ore, etc. It is also one of the most commonly used crushing equipment in the compound fertilizer industry. It is suitable crushing for materials with high moisture content. With strong adaptability, it is not easy to block, and unloads smoothly, which can promote your npk fertilizer production working efficiently greatly.

Technical structure of the vertical fertilizer crusher used in npk production industry

The vertical npk crusher adopts vertical shaft up and down placement, making full use of the weight of the material itself and reducing the power consumed in the process of compound material crushing. The fertilizer grinder machine is mainly composed of three parts:

- Mechanical transmission part;

- Impact crushing part;

- Hammer the broken part. Among them, the hammer crushing part and the counterattack crushing part play a major role. By this structural design, the material can successfully achieve the purpose of reducing particle size through counterattack crushing and cone crushing.

Specifically, the vertical fertilizer pulverizer is composed of cylinder, rotor, cover accessories, base and other parts.

Cylinder body: It is composed of casing, door, partition and counterattack plate, and each part is connected by welding bolts and screws. There is a counterattack plate inside the casing, and the counterattack plate can be replaced separately after wear.

Rotor: It consists of a main shaft and a hammer frame. The hammer frame adopts eccentric pins to hang the hammer heads between the hammer frames in 4 rows. The rotor is supported on three rolling bearings.

Machine cover: It consists of machine cover, rolling bearing, tapered sleeve, upper bearing cover, upper sealing ring, round nut and straight-through oil cup, which are connected together with bolts.

Base: It consists of supporting sleeve, rolling bearing, lower bearing cover, lower sealing ring, shaft sleeve, gasket, oil filling device, base, etc., which are connected together with bolts. The base is used for the positioning of the entire rotor shaft.

Design requirements for important components of the vertical shredder

- There is an impact plate inside the casing of the vertical shredding equipment. The impact plate adopts a ribbed structure with the best effect, because the sharp corners of the prism body have high casting quality, high hardness after heat treatment, and strong wear resistance. The impact plate is made of wear-resistant alloy steel. Conducive to the extension of the life of the impact plate.

- The phenomenon of ash leakage between the cover and the shaft is serious. In order to prevent ash leakage, a shaft seal is provided.

- The main shaft is the main part of the vertical crusher supporting the rotor, and the impact force is borne by it. Therefore, the material of the main shaft is required to have high hardness and toughness.

- The hammer frame is used to install the hammer head, but when the vertical crushing equipment reverses, the hammer frame and the material contact easily cause wear, so the selected material should also have certain wear resistance.

How to make npk powders by the vertical shredder?

The npk fertilizer materials falls vertically into the high-speed rotating impeller from the upper part of the vertical shredder machine. Under the action of high-speed centrifugal force, the other part of the material shunted around the impeller in the form of an umbrella produces high-speed impact and crushing. The material layer between the shells forms eddy currents, which are repeatedly impacted and rubbed and crushed, and are discharged from the lower discharge hopper.

What technical design highlights we use in the vertical fertilizer grinding machine?

- The blow hammer and the rotor are rigidly connected. Using the inertia of the entire rotor to impact, a larger speed and kinetic energy can be obtained, making it easier to break and lower energy consumption.

- The structure of the crushing cavity is designed to be large, so that the material has a certain space for movement in the vertical shredder, and the material is subjected to impact, and can be fully broken after repeated blows.

- The crushing ratio is large, which can reach about 15-20mm, which is conducive to reducing the crushing section, simplifying the technological process, saving investment and reducing npk production costs.

- The structure is simple, easy to produce, and the operation and maintenance are also very convenient.

- The new hammerhead structure design is adopted, the traditional integral structure design is abandoned, and the combined structure design is adopted. Only the severely worn parts need to be replaced, which greatly improves the service life of the hammer head, and effectively reduces the production cost and the replacement frequency of the wearing parts of the fertilizer vertical crushing equipment.