Straw Crusher for Sale

- Max. Capacity: 15 ton/h

- Voltage: 380v

- Dimension(L*W*H): 380*100*105mm

- Weight: 800 kg

- Core Components: Gear, Motor

- Color: Customer’s Request

- Rotate speed: 2800r/min

- Material: Durable Carbon Steel

- Application: Make Animal Feed

- Power: 38kw

Get Price Now!

Description

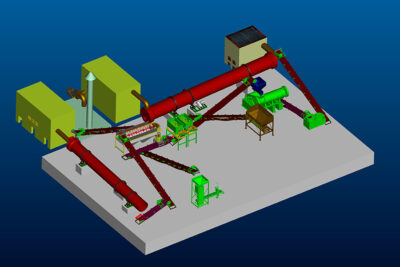

In organic npk fertilizer production process, to adjust the n/c or the moisture content ratio for quality commercial fertilizer production, it needs to add some auxiliary materials in the fertilizer production main materials, like cow dung, chicken litter.

Straw Crusher for Organic NPK Raw Materials Processing

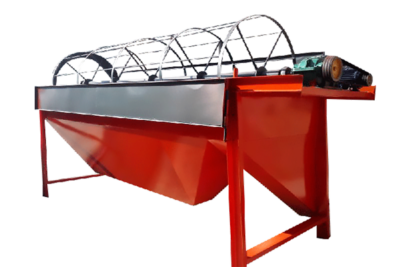

Straw is the most common used auxiliary materials in the fertilizer production process. While, before use it in the npk composting process, it needs to shredding first. The straw compost shredder is often used to grind straw into fine powder.

The pulverization of wood chips and the fine powder making of coarsely broken materials are also one of the most important processes in wood processing plants. They are also the sections with the largest power consumption, which generally account for 30%-50% of the total energy consumption of the entire wood plant. One of the important ways of energy consumption. The wood chips and coarsely crushed materials are hit and rubbed by the rotating hammer in the crushing cavity, so that the crushed materials form smaller particles than the original particles.

How to make straw powder with a compost shredding machine?

In the pulverizer with sieve, when the wood chip material is pulverized by the straw pulverizer or the straw crusher, the whole process of the pulverization operation has not been completed. And the particles that have been pulverized to meet the particle size requirements. Thus, it must be discharged out of the fertilizer grinder machine through the sieve hole to complete the whole process of pulverization. Therefore, the pulverization operation of the sieve sawdust pulverizer should include two stages of shredding. Only by this way, the wood chip material can reach the particle size powder through the sieve holes.

As the manufacturer of sawdust straw powder making machines, we have carried out a long-term research and improvement, which has improved the pulverizing efficiency of the sieved sawdust pulverizer to varying degrees. By improving the structure of the existing wood chip fertilizer grinder, the pulverizing efficiency can be increased by 10% to 20%.

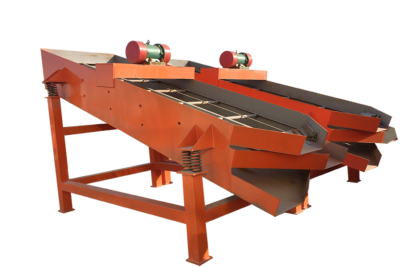

Straw powder making machine main structures

The composition of the straw pulverizer system is usually composed of a pulverizer feeder, a pulverizer, a sealed horizontal conveyor, a pulse bag filter (including a fan) and a vertical bucket elevator. Whether the determination of each part of the parameters is correct or not, and whether the equipment layout is reasonable or not have different degrees of influence on the crushing efficiency.