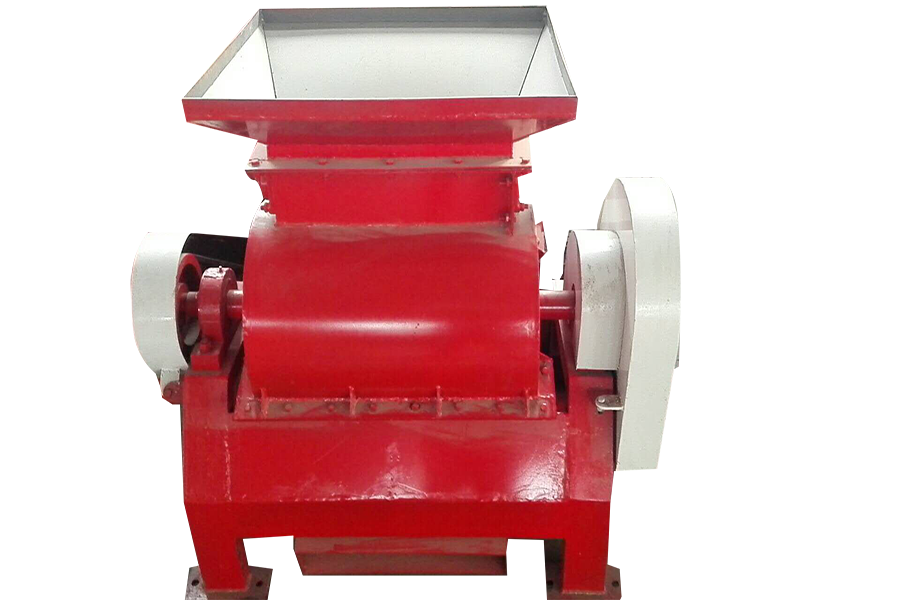

Urea Crusher for Sale

- Motor Type: AC Motor

- Capacity(t/h): 1t/h

- Dimension(L*W*H): 4700x1250x2900mm

- Weight: 1010 KG

- Warranty: 1 Year

- Core Components: Motor

- Central Distance: 400mm

- Capacity: 1t/h

- Inlet Granularity: <10mm

- Discharging Granularity: ≤1mm(70%~90%)

Get Price Now!

Description

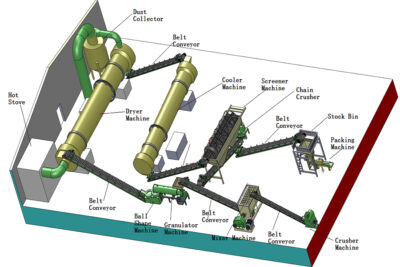

Urea crusher can make npk materials into fine powders with 1 to 8t capacity per hour. The npk crusher is used for shredding various brittle materials, such as granular urea, compound fertilizer, coal, slag, shale, loose limestone, etc. The compressive strength of the crushed material does not exceed 12MPa, and the surface moisture is less than 13%.

Why you need to buy a urea npk powder making machine?

When producing compound fertilizers, some chemical fertilizers need to be mixed into the raw materials as auxiliary materials. When batching, the materials need to be pulverized into powder and sent to the batching bin. For example, we can use a urea pulverizer to crush large urea particles. It is made into fine powder, which is convenient for weighing and measuring in automatic batching equipment, and it is also convenient for subsequent production of granules.

Types of urea fertilizer grinding machine

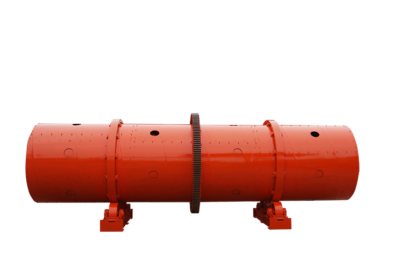

Some chemical fertilizer raw materials are easy to stick into lumps at room temperature, especially in the npk compound fertilizer production workshop with a slightly higher temperature, products such as urea are easy to form large lumps. Thus, a urea pulverizer needs to be used to grinder them before use. At present, there are two types of urea grinders, one is a single-roller crusher, and the other is a cage crusher.

The single-roller urea pulverizer is driven by a motor. And there is only a drum-type pulverizing device inside the pulverizing cavity. During operation, it rotates at a high speed under the drive of the electric motor. By this way, the material entering the pulverizing cavity from the feeding port is broken into powder. Although this fertilizer pulverizer has only one pulverizing drum, the pulverizing effect can be adjusted by adjusting the gap between the drum and the inner wall of the casing, and the effect is also very good.

The structure of the cage-type urea crusher is completely different. It is driven by two motors to drive the two cage-type drums to rotate at a high speed. The large pieces of urea material entering the drum are continuously impacted in the gap between the two drums. A good crushing effect is achieved. In organic compound npk fertilizer production equipment, these two types of pulverizers have their own applications, and customers can choose and buy according to your own needs.

Technical specifications for the npk urea fertilizer grinding machine

| Model | NSFSJ650 | NSFSJ 750 | NSFSJ 900 |

| Rotor Sizes (mm) | 520 | 600 | 600 |

| Rotor Length(mm) | 650 | 750 | 900 |

| Feed particle size (mm) | 30 | 30 | 30 |

| Discharge particle size (mm) | ≤0.2 | ≤0.2 | ≤0.2 |

| Capacity(t/h) | 4 | 6 | 8 |

| Power (kw) | 18.5 | 22 | 30 |

| Rotating speed (r/min) | 1440 | 1440 | 1440 |

| Weight (tons) | 0.8 | 1.1 | 1.3 |