Phosphate Ammonia Potassium Fertilizer Production Line

- Production Capacity: 10,000 to 200,000t Annually Organic NPK Fertilizer Production

- Turnkey Project Solutions:Provided

- Customized Services:Provided

- Installation:Provided

- Main Equipment:Grinder, Blender, Conveyor, Granulator, Dryer and Cooler, Coater, Packer, etc.

Get Price Now!

Description

At present, the development of compound fertilizer production in the world has gradually shifted from low concentration to high concentration. Due to the different grades of phosphate rock in different countries, various enrichment processes must be carried out to produce high-concentration compound fertilizers.

Phosphate Ammonia Potassium (PAP) Fertilizer Production Line for Sale

The production of high-concentration compound fertilizers with or through ammonium phosphate is a commonly used form of processing. The following briefly introduces the production process of ammonium phosphate ternary compound fertilizer.

NPK Fertilizer Production process

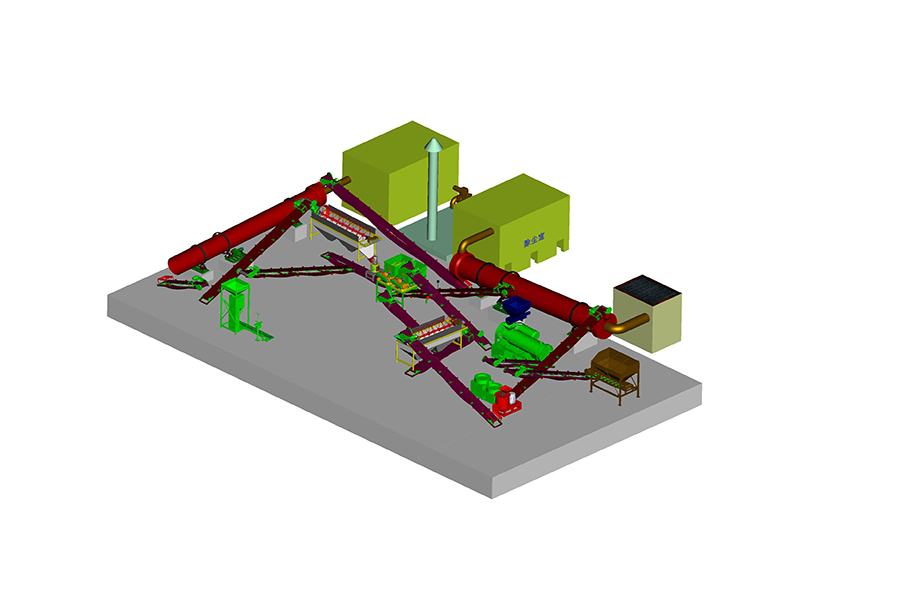

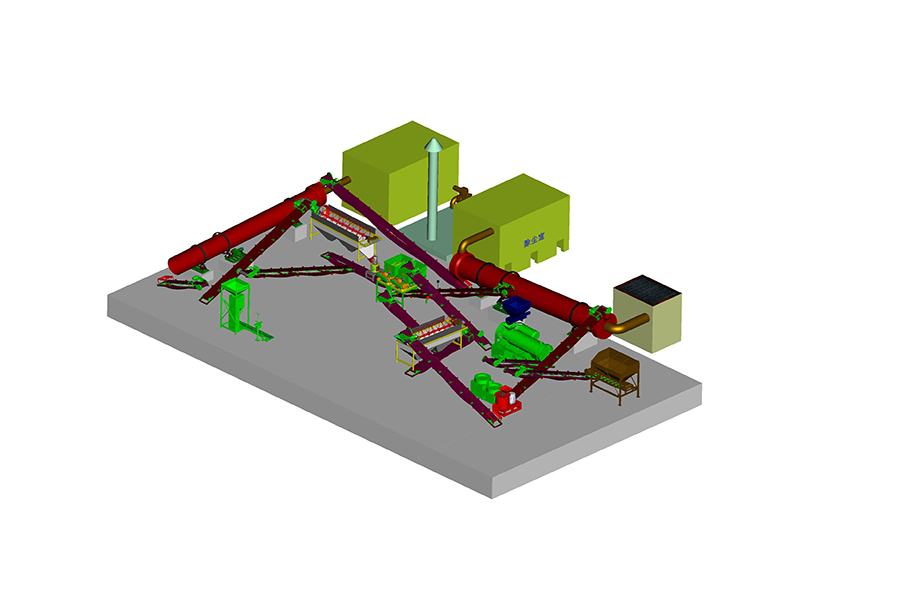

The process flow of ammonium phosphate slurry ammoniated granulation to produce compound fertilizer is shown in Figure 3-7.

The principle of this method to produce compound fertilizer is to produce ammonium phosphate slurry, which is pumped into a granulator and blended with urea, potassium chloride, additives and return materials, and then granulated.

It is sent to the rotary dryer machine for drying. The products obtained by drying must be classified by a three-layer vibrating screen due to their inconsistent particle specifications. The qualified products from the middle layer are packaged and shipped, and the unqualified particles from the upper and lower layers are returned for reprocessing.

Process conditions for the npk fertilizer production

- Ammonium phosphate slurry temperature: 80℃

- Dryer inlet temperature: 165~ 185℃

- Dryer outlet temperature: 70~ 80℃

- Granulation rate: > 50% .

- Finished particle size: 1 ~ 4mm≥80%

- Finished moisture: ≤5%

Main Equipment used in the npk compound fertilizer production line

The compound fertilizer production equipment with an annual output of 30,000 tons is shown in Table 3-1.

| Product Name | Specifications &Model | Quantity |

| Rotary Drum Dryer | i=10; V==88.3m3; ⌀2500*18000mm; n=3r/min | 1 |

| Drum granulator | i=20; ⌀2000*4500mm; n=10-17r/min | 1 |

| No. 1 Vibrating Screener | 3000mm*1200mm; Screen Size:4.37mm; HS1230 | 1 |

| No. 2 Vibrating Screener | 3000mm*1200mm; Screen Size:1.5mm; HS1230 | 1 |

| Bucket elevator | Q=30~47m3/h; H=28.52m; HL400 | 1 |

| Cyclone | 6-⌀700mm; V=20m/s; Q=21780~26400m3/h; CLT/A6*7 | 1 |

| Exhaust exhaust fan | Q=32000~3500m3/h; H=454~357. mmH2O; 9-20No.14 | 1 |

| Double Shaft Chain Crusher | ⌀600*800mm; Q=16t/h; NE078-18 | 1 |

| Burner | F=2.5m2; Q3400m3/h | 1 |

| Fan | Q=16200~27960m3(Standard)/h; H=164~158mmH20;Ca-4b | 1 |

| Secondary fan | Q=4725~7420m3(Standard)/h; H=206~115mmH20; 4-72No.BD | 1 |

| Electric hoist | Q=3t; H=18m; CD3-18 | 1 |

| Return belt conveyor | B=500mm; L=1370mm; TD75 | 1 |

| Finished belt conveyor | B=500mm; L=21000mm; TD75 | 1 |

| Exhaust scrubber tower | ⌀2000*8720mm | 1 |

| blender | V=400L JG250; 151 Type | 1 |

| Slurry pump | NE078-7; Q=7m3/h; H=30m | 1 |

| Electronic belt scale | B=500mm; L=3800mm; CGP-20 | 2 |

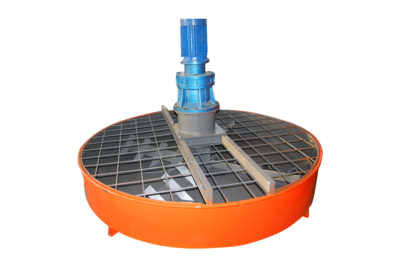

The key in compound fertilizer production equipment is the granular fertilizer pelletizer . Ammonia granulation can be used drum granulator, the structure of which is shown in Figure 3-8. The rotary drum granulator is a horizontal drum with a certain inclination and is equipped with a rotary scraper. In order to mix the slurry and the solid material evenly, a slurry distributor or nozzle is installed.

In addition, a spheronizer can also be used for granulation, and this device can also perform drying and granulation at the same time. During this process, the potassium-containing, neutralized slurry is sprayed against the solid particles to form mist droplets. The drying air and the shotcrete are blown downstream, and the inlet temperature can be 180~200℃. Since the granules are sprayed for multiple cycles in the spheroidizer, layered granulation can be achieved, and the water can be quickly evaporated. Most of the particles from the drum meet the size requirements as finished products, and some of the particles that do not meet the specifications can be recycled. The temperature of the product coming out of the spheroidizer is about 90°C, and the finished product is sent to sieving, scooping and anti-caking treatment.