Wheel Type Compost Turner

- Core Components: Engine, Bearing, Gearbox

- Voltage: 380v

- Weight: 8000 KG

- Raw Material: Organic Manure

- Turning Width: 4000mm

- Turning power: 22kw*2

- Moving power: 3kw

- Working speed: 30-90m/h

- Turning depth: 1800mm

- Turning tooth thickness: 8mm

Get Price Now!

Description

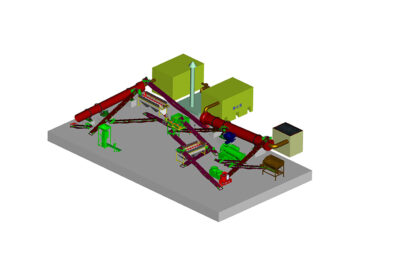

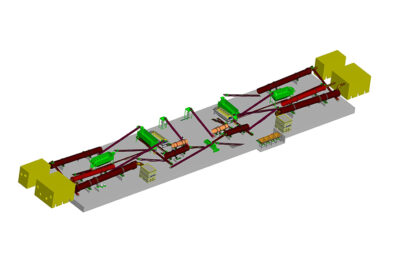

The wheel type compost turning machine adopts the intermediate chain transmission mechanism to drive the two-diameter turning and composting roulettes, and the turning and throwing is symmetrical. The speed-adjustable shifting trolley without dead angle can move left and right, and complete the large-span composting work with low energy consumption.

When the depth of the compost material is deep, the wheel-type turning machine uses a small power to complete the high-depth and large-span turning planning operation through the energy-saving transmission mechanism. Its hydraulic lifting system can automatically lift and lower the large-span hydraulic double-disc turner tray to ensure that the equipment can move without obstacles. In addition, the supporting fully automatic electrical control system further ensures that the compost equipment is easy to operate, safe and reliable. The large-span chicken manure turning and throwing fermentation equipment can be customized with different spans according to the width of the fermentation grooves.

What does the wheel compost machine can do in your fertilizer production line?

The roulette type turner is mainly used in the fermentation process of organic fertilizer production. It is an intensive product integrating overturning, stacking, oxygenation, crushing and mixing. It has strong working ability, wide application range, automatic.

High degree of chemicalization features: The overall structure of the machine is reasonable, the whole machine has good rigidity, balanced force, concise, strong, safe and reliable performance, easy to control, and has strong applicability to the site. Except for the thick frame, all parts are standard.

Standard parts, easy to use and maintain.

Why to buy this type of compost turner machine for your large-scale composting plants?

- The processing capacity is large, the investment in civil construction is low, the depth of the fermentation groove is 1.5m-2m, and the width of the trench can be 8-30m, which can save the wall of the fermentation groove compared with multi-grooves. Save civil construction costs.

- Using chain drive, the main power of the machine is separated from the reducer, which is convenient for maintenance and effectively reduces the failure rate of the reducer. ,

- The disc blade is equipped with 30 high-hardness reinforcing sheets, which have high wear resistance and can be replaced in time, which is convenient and flexible.

- When flipping, the material is lifted into the air and scattered at a high position. It is in full contact with the air and is easy to water.

- Through horizontal and vertical displacement, the flipping operation can be realized at any position in the tank, without dead angle and flexible.

- The lifting and lowering of the turning and throwing working parts is controlled by a hydraulic system, which is flexible and safe and fast.

- It can remotely control the machine, lift, move forward, traverse, flip and quickly retreat, and can remotely change the speed according to the nature of the material and on-site conditions, thereby greatly improving the operating environment.

- Optional trough-type raw material distributor, automatic discharge device, solar fermentation chamber and ventilation and aeration system, etc.

- It can save the line-feeding equipment and supporting civil construction investment.

Why to choose us as your compost turner manufacturer?

We are a manufacturer of compound fertilizer equipment and organic fertilizer equipment. We strictly manage according to IS09001-2000 quality system certification standards. To produce organic fertilizer production lines, our factory has strong strength, technical force, and cold and hot processing capabilities. We have a workforce, a CAD design center, and high-precision processing equipment (such as 3 automatic laser cutting machines and 10 processing centers.)

How to extend your wheel type compost turner for sale service life? (Maintenance and Operation)

- The turning machine wheel type for composting is in direct contact with the material when it is working, and its corrosiveness is strong. Therefore, the dirt stuck on the turning machine, especially the dirt on the chassis should be cleaned up in time, and if the protective paint falls off, it should be brushed.

- The tightness of the transmission chain should be checked frequently and adjusted in time. When the adjustment tension still fails to meet the requirements, a few chains can be removed to make them meet the requirements; if it is found that the rotation between the chain links of the transmission chain fails, it should be lubricated with butter or oil in time; the walking support bearings on the chassis, stirring the shaft rotating support (integrated with the above) lifting support bearing should be regularly lubricated with grease.

- The gear box must be checked for oil before it is used, and the new oil should be replaced after one hundred hours of operation, and the new oil should be replaced every one thousand hours of operation. The time interval is one year.

- After the hydraulic system has been running for 200 hours, all hydraulic oil should be prevented and controlled, the impurities in the filter of the hydraulic system should be removed, and the filter element should be checked whether it is necessary to replace the filter element; according to the cleanliness of the discharged hydraulic oil, decide whether to reuse it after filtering. When discharging hydraulic oil, the cylinder rod should be retracted into the cylinder barrel first; the hydraulic system should be cleaned every 800 hours of operation.

Technical specifications for the wheel type compost turning equipment for sale

| Model | Details |

| Power(KW) | 22-30 |

| Turning Diameter | 1500mm-2000mm |

| Heights | 1500mm-2000mm |

| Working Speed | 8-10M(Horizontal) |

| Capacity | 300-500m3 |

| Ttransferring Distance | 3-4m |

| Lfitting Heights | 1800mm-2200mm |

| Trench Heights | 1700-2000mm |

| Motor Power(Hhorizontal) | 1.1KW Remote control frequency conversion speed regulation(2sets) |

| Motor Power(Vertical) | 1.1KW Hand Power frequency conversion speed regulation(2sets) |

| Hydraulic Motor Power | 3KW |