Fertilizer Production Plant for Sugar Mill Waste Disposal

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Sugar Cane

- Industry Serviced: Sugar Factory Waste Management, Sugar Cane Litter Disposal

- Complete Set of Machine:Provided

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

The wastes of sugar cane factories include waste residue, filter mud and waste liquid, etc., which are rich in organic matter and various nutrients required for plant growth. It is a valuable agricultural resource and can be used as feed and fertilizer. The waste can be fermented and retted to produce compound fertilizer, which can not only improve the efficiency of sugar mills, recycle resources, but also reduce waste discharge and solve environmental problems. It is estimated that in some areas of Malaysia, the annual output of dry filter mud is 200,000 tons, which can produce 50-100 tons of organic compound fertilizer, which provides feasibility for industrial production of compound fertilizer.

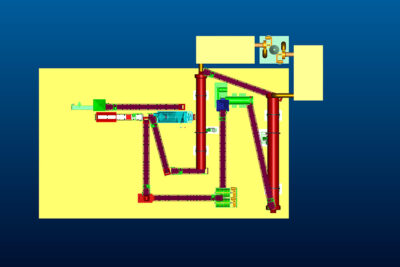

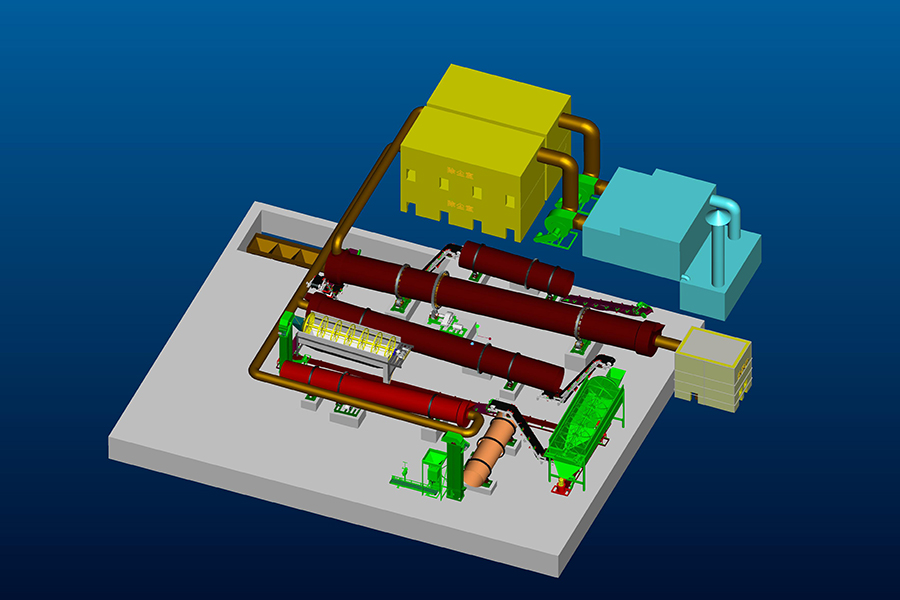

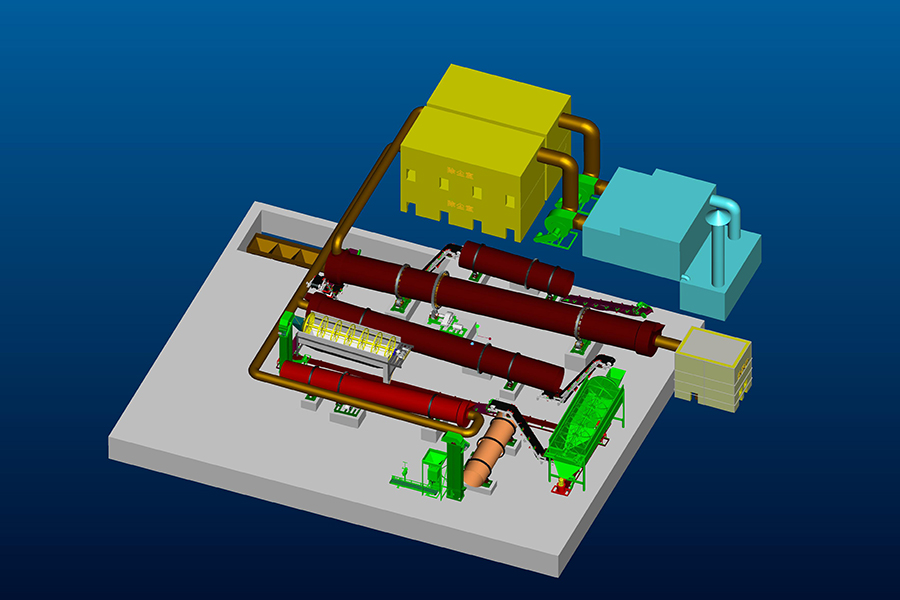

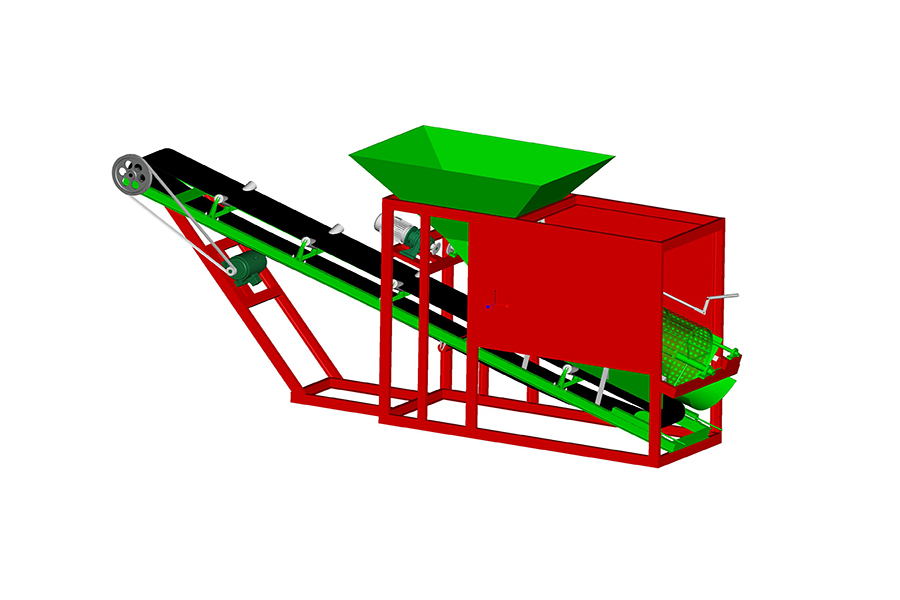

The process of producing compound fertilizer from sugar mill waste is shown in Figure 6-2.

The waste composition of the cane sugar factory is shown in Table 6-13.

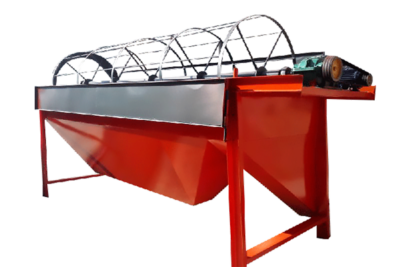

The production of compound fertilizer from waste must also be formulated according to the soil characteristics and crop demand in various places. At the same time, the amount of inorganic fertilizer nitrogen, phosphorus and potassium should also be considered depending on the amount of nutrients contained in different sugar mill wastes. The process and equipment for producing compound fertilizer from sugar mill waste are basically the same as those described above, except that the drying temperature is slightly lower than that of ternary compound fertilizer, and should not exceed the decomposition temperature of organic matter. Compound fertilizer products produced from sugar mill waste can be granular or powdered, that is, blended fertilizer. The quality standard can refer to the quality standard of ternary compound fertilizer.

The production of organic compound fertilizer from sugar mill waste can be used as base fertilizer or as top-dressing fertilizer. More waste is used as base fertilizer, and less waste is used as top-dressing fertilizer. It has a good effect on sugarcane, and the application amount per acre is about 200kg. Practice shows that the application of the compound fertilizers listed in the table above can increase the yield of sugarcane by 1.16 to 1.18 times. For rice, fertilize 50kg per mu in the early season and 60kg per mu in the late season, of which base fertilizer, tiller fertilizer, strong tiller fertilizer and differentiation fertilizer each account for 25%.

Using sugar mill filter mud to produce organic compound fertilizer, the ratio is reasonable, the nutrients are complete, the organic and inorganic nutrients account for about 54%, not only contains nitrogen, phosphorus and potassium elements, but also contains an appropriate amount of magnesium, calcium, sulfur, silicon and essential nutrients for plant growth. trace elements. The fertilizer has quick-acting nutrients and long-acting nutrients, and can be used to cultivate land in the body. It can not only inhibit the loss of effective nutrients, improve the absorption of nutrients by crops, enhance the ability of disease resistance and disease prevention, but also balance the organic matter and inorganic matter of the soil to achieve the effect of increasing yield.