Hot Blast Furnace for Sale

- Application: Medicine Processing, Chemicals Processing, Food Processing, Chemical, food, building materials, etc

- Voltage: 220V/110V

- After-sales Service Provided: Field installation, commissioning and training, Engineers available to service machinery overseas

- Usage: drying

- Material: Stainless steel

- Fuel: Oil, coal, gas,biomass

- Melting Capacity: as customer requirements

- Working Temperature: as customer requirements

Get Price Now!

Description

Gas hot blast furnace is a kind of heating equipment that uses oil and gas as fuel, air as heat carrier, forced circulation by fan, heat exchange by heat exchanger and filtration by air filter, and output of clean hot air. Gas hot blast stove in our factory is divided into direct-fired gas-fired hot blast stoves and indirect heat-exchange gas-fired hot blast stoves. It has the characteristics of extremely high thermal efficiency, fuel saving, low operating cost, good heat exchange effect, no local heating of the furnace body, and long service life.

Hot blast furnace working performance

- Direct-fired gas hot blast stove features

It is mainly composed of valve assembly, burner, combustion chamber, secondary air distribution and control system.

Through the valve assembly, it is fully mixed with the air at the burner, and the clean high-temperature flame is directly injected into the combustion chamber to generate clean high-temperature flue gas.

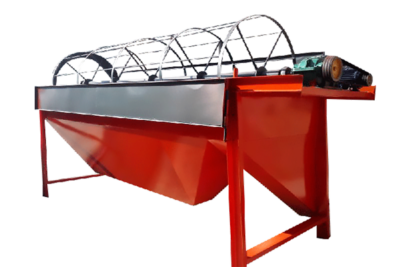

The required hot air temperature, the hot air enters the fertilizer drying equipment (such as drying room, oven, tumble dryer, mesh belt dryer, airflow dryer, etc.) through the hot air duct to dry the material.

The hot air is clean and the thermal efficiency is high, up to 100%. Less auxiliary equipment, low investment cost, good operating environment; easy operation, manual/automatic control: with automatic ignition, load section and flame detection and alarm functions.

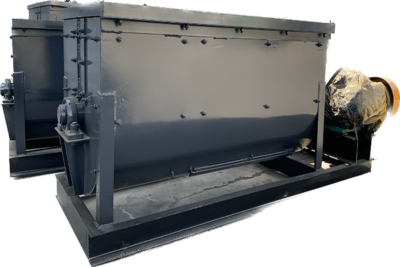

- Indirect heat exchange gas hot blast stove working performance

It is mainly composed of combustion system, heat exchange system, control system and exhaust system.

Combustion by the burner generates high-temperature gas, which heats the heat exchanger system, and the heated air is sent to the drying system through the blower. Thermal efficiency can reach 92%. When the hot air temperature in the drying system reaches the upper limit of the rated temperature, the burner will automatically stop burning or automatically turn to small flame burning. When the temperature of the hot air drops to the lower rated temperature, the burner will re-ignite or turn into a large fire burning. The speed of heating can also be achieved by adjusting the air inlet valve.

Advantages: High heat exchange temperature, high heat utilization rate, small volume, stable hot air temperature, long service life and low maintenance cost.

- High thermal efficiency, fuel saving and low operating cost.

- The structure is compact and the volume is not too large, which is convenient for transportation and installation.

- The heat exchange effect is good, the furnace body is not heated locally, and the service life is long.

- The hot blast stove fully absorbs heat, and the temperature of the flue gas emitted by the chimney is low, which is energy-saving and efficient to use.

Get a Free Quote with Detailed Price Lists, Inquiry Us Now