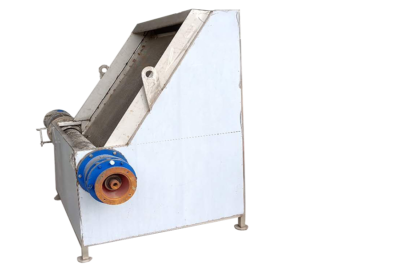

Fertilizer Polishing Machine for Sale

-

- Output (kg/h): 8000

- Core Components: Engine, Gearbox, Motor, Gear

- Voltage: 380v

- Dimension(L*W*H): 3200*1550*1600mm

- Weight (KG): 822

- Power (kW): 22

- Applicable Industries: Chemical & Machinery Equipment

- Matching Power: 11*2kw

- Disc Diameter: 1500mm

- Shape Size: 3200*1550*1600mm

Get Price Now!

Description

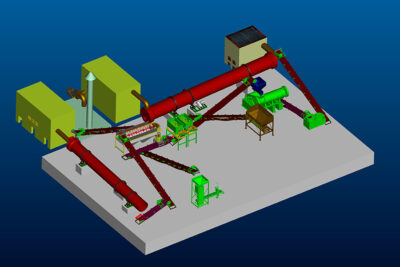

The fertilizer polishing machine manufactured in our factory is a ball shaping equipment for granules made from pan granulators, drum granulators, extrusion granulators, flat die granulators, etc. It will be shaping the fertilizer pellets at one time. Granules after polishing will be more beautiful, strengthen and easier to apply with the fertilizer application equipment. The circular polishing machine can be used for the beauty of all granular fertilizers. Such as, it can polish the granular fertilizer produced by extrusion granulation or disc granulation process.

Fertilizer Polishing Machine for NPK Fertilizer Plants

During the polishing process, it can make the fertilizer particles uniform in size, accurate in roundness, bright and smooth on the surface. Furthermore, its fertilizer polishing rate is as high as 98%. Buy one for your npk production line, it will reduce the material returning, so it can reduce energy consumption and increase output of the compound fertilizer production. The granules after polishing have low moisture content and are easy to dry. At the same time, it can also produce feed pellets, which is an ideal equipment for organic compound fertilizer pelletizing.

How to make rounder npk granules with the fertilizer polishing machine?

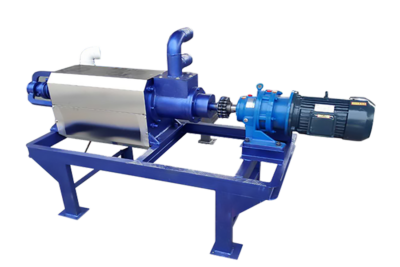

The organic fertilizer rounder is a multi-layer continuous organic fertilizer particle polishing and shaping equipment.

- A large cylinder is fixed on the top of the frame, and the upper end of the large cylinder has an upper cover.

- There is a large turntable at the lower part of the big cylinder. A vertical shaft is connected with the frame by two bearings.

- The lower end of the vertical shaft is connected with the output shaft of the motor through a reducer or a pulley.

- While, the outer edge of the large turntable is connected in sliding contact with the inner wall of the large cylinder.

- There is a discharge chute connected to one side of the big cylinder and under the big turntable.

- After the raw material particles enter the rounder and are rounded.

- They enter the next rounder or feeder through the discharge port on one side, and the powder is discharged from the discharge chute under the large turntable.

- What materials can you use the deburring and polishing fertilizer equipment?

- The fertilizer pellets polishing machine is suitable for rounding the granules of organic fertilizer and compound fertilizer. Thus, it can polish different types of granular made by different types of organic and compound npk fertilizer production materials.

- Polish organic npk pellets, like chicken manure pellets, cow dung pellets, wood pellets, etc.

- For complex npk fertilizer prills round shaping, like npk granules made by based fertilizer raw materials.

- Bio-npk granules polishing, like bio npk pellets produced with grass ash, lignite, organic fertilizer sludge, straw, etc.

How to buy a quality fertilizer polishing equipment for your fertilizer production line?

- Buy an easy to configure one. The organic fertilizer rounder can effectively improve the appearance quality of particles. Thus, you can buy one flexibly according to product needs in the npk production process.

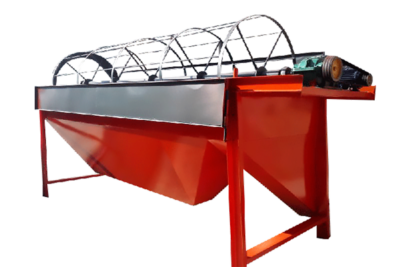

- Buy a hinger working efficient polisher for your fertilizer production project. The machine is composed of two or three throwing cylinders arranged in sequence. After the material is thrown round several times, the finished product is discharged from the discharge port. The particle size of the finished product is consistent, round and smooth, and the yield is as high as 98%. And a small amount of fertilizer powder falls from the gap of the disk edge of the organic fertilizer rounder and is discharged along the waste port.

- Buy a polisher for sale with compact structure. The organic fertilizer rounding machine has beautiful appearance, simple structure and working principle. Reliable installation, small size, light weight, easy operation and maintenance.

- Buy one with wide-spread application fields. The organic fertilizer rounding equipment has strong adaptability and can adapt to work in various environments, and the organic fertilizer rounder can maintain continuous operation for a long time, with low power consumption, low power consumption, low production cost and high economic benefits.

Fertilizer polisher for sale installation debugging

After buying a fertilizer polisher for your npk factory, the next important thing is to use it. While, how to use it quickly? The first is to install and debug it. In the following, we provide you tips to install, debug the fertilizer polishing equipment.

How to installation the polisher fertilizer production equipment:

- You can install the fertilizer granules polishing equipment on the level cement floor. Additionally, the belt conveyor for conveying fertilizer materials should be aligned with the inlet and outlet. It is easy to install on your npk production line.

- Debug the organic npk pellets polisher in the fertilizer producing process

- When you finish the installation work, it is necessary to check the granules polisher whether all its parts in normal working status.

- Be sure that, the parts are fastened.

- Check whether there is friction between the turntable and the cylinder.

- Then carry out no-load test run. The machine relies on the rapid rotation of the rounding disc to round the npk particles. There is no requirement when testing, but there should be no vibration during the test run. Moreover, the temperature of each bearing rises steadily. Meanwhile, the temperature of each component should not be higher than 50°C when you finish the test run work.

- How to maintenance the granular round shaping equipment?

- You should replace its bearing parts with lubricating oil every three months. And the oiling model is No. 3 calcium-based grease lubricating oil.

- Wearing parts for the fertilizer pellets polishing production machine:

- You should replace its wearing components every 6 months: a. Bearing b. V-belt

Instructions for operation the fertilizer granular polishing machine

- When turning on the machine, you should pay attention to whether there is any abnormal noise. If there is, you should turn off the power immediately, and then turn on the machine when finding out the cause.

- When starting up, the machine behind the rounder should be turned on first. And then the fertilizer npk rounder should be turned on after it is running. The last is to turn on the feeding; when shutting down, you should turn off the feeder first. While, the machine should be turned off after the material inside the machine is discharged. Power supply, reverse operation is strictly prohibited.

- It is strictly forbidden to start the machine with load.

Technical parameters for the fertilizer polishing machine

Want to buy a fertilizer polishing machine for your npk plants? Want to know what’s the cost of the polisher? Need to get price quotations, inquiry us now.