Static Batching Machine for Sale

-

- Core Components: PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear

- Power Type: Electric

- Place of Origin: Henan, China

- Weight: 18000 kg

- Warranty: 1 Year

- Application: Organic Compound Fertilizer Production Line for farm

- Raw material: Animal waste/NPK fertilizer

Get Price Now!

Description

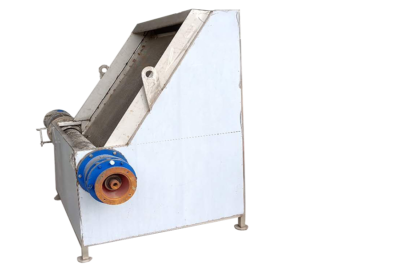

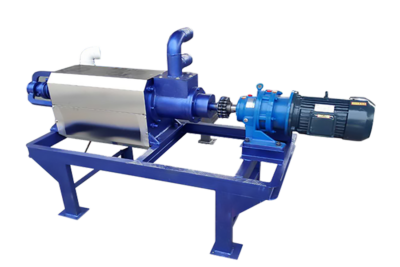

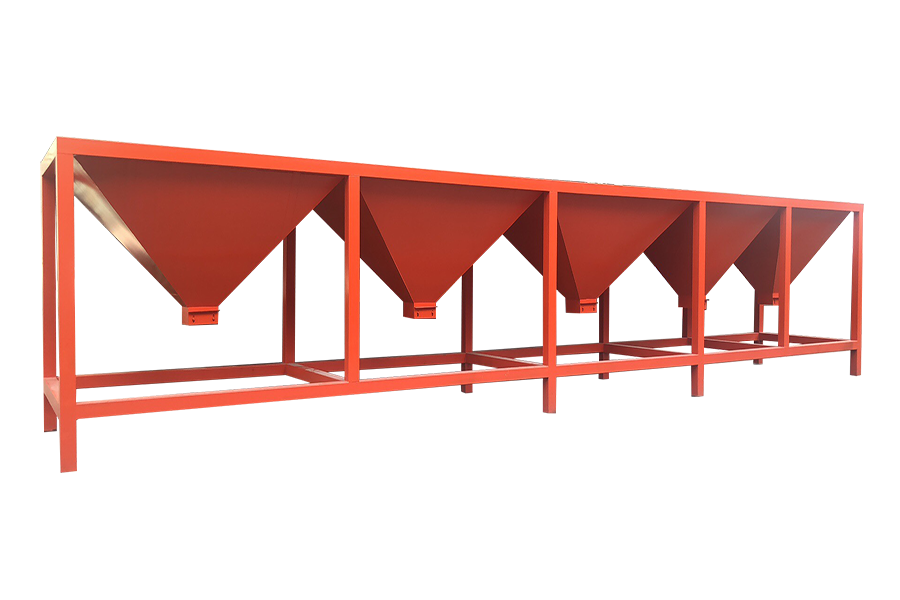

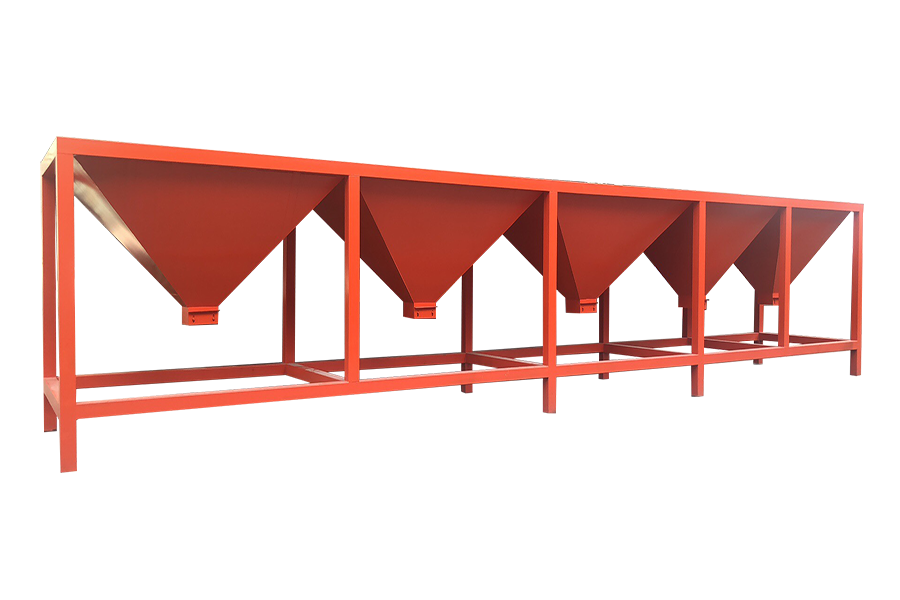

Static batching machine is an auxiliary fertilizer production equipment in organic compound or npk fertilizer plant. Combined with other machines, like fertilizer blenders, crushers, fertilizer pelletizers, bagging equipment, it will help you make fertilizer automatically and efficiently. The multi-silo fertilizer batching equipment is a pre-mix equipment for different types of fertilizer ingredients in organic compound fertilizer production lines. The main parts of the static batching fertilizer machine include: fertilizer silos, indexing drive device, silo position identification device, screw feeder, clutch device, drive motor, sealing device, electronic scale, mixer.

Static automatic batching system structural design

The static fertilizer batching equipment is a precision instrument for fertilizer production. Every system we make for this batching machine adopts high technology. How does each batching system connect with each other for efficient fertilizer batching process? The following are details:

The indexing drive device and the fertilizer silos in the batching system will working together for continuous running of the fertilizer machine.

Position identification tool connects with each fertilizer silo will let you feeding fertilizer materials easily.

Under the fertilizer silos’ bottoms, there are screw feeders, which let your make fertilizer mixture in the nest process more convenient.

On the output shaft of the drive motor, it installs clutch device, which help you batch fertilizer more safely.

For precise batching, there designs a sealing device on the electronic scale.

At the lower silo of the electronic scale, there is a discharge door for materials fluent output.

After raw materials batching, it needs to mix all different kinds of materials together. Thus, we install a mixer under the electronic scale. It is quite useful for the next npk granulation process.

At the lower silo of the mixer, there installs a discharge cover for quality fertilizer batching.

Why choose a static batching machine for your npk fertilizer production plant?

- with high-reliability frequency conversion speed regulation technology, wide belt, thick material layer, low-speed operation, so it has stable operation and close to static measurement accuracy. The dynamic measurement accuracy is better than 1.0%; the static measurement accuracy is better than 0.5%, and the precision type can reach 0.125%. In quality npk fertilizer production industry, it will be your best choice in the nutrient npk production plants.

- The automatic quantitative adjustment of the automatic batching machine has high precision and wide adjustment range (speed adjustment ratio ≥ 20:1, belt speed 5cm/min ~ 15m/min).

- It still has good linear speed regulation performance at low speed, which can greatly reduce the wear of the belt and avoid the damage of large materials. With this structural design, you can use the machine for a longer time than other traditional batching equipment.

- Higher working performance. After continuous improvement and perfection, automatic belt centering, automatic tension adjustment, profiling cleaner, and roller bearing dust-proof design in line with the fertilizer static batching machine. The control precision is high, the stability is good, and the price is only 1/4~1/5 of the imported similar products.

- The operation and maintenance cost of the automatic batching machine is low. Under normal operation, the service life of the endless belt can be as long as 5 years. What’s more, you can save 20-40% electricity than the traditional ones. In maintenance design, the special fast belt replacement method can quickly replace the belt with only two people.

- Customize for your npk fertilizer production line. According to the technological requirements of the enterprise “tailoring”, carry out on-site design to ensure reasonable selection and reliable operation. Flexible configuration, you can buy a best suitable one for your own fertilizer production plant.

Static Batching Machine Technical Specifications

For more detailed information about the static batching equipment, welcome contact us now.