Cow Dung Drier for Sale

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Cow Farm Manure

- Industry Serviced: Cow Farm Waste Management, Animal Farm Litter Disposal

- Complete Set of Machine:Provided

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

Product introduction of cow dung dryer

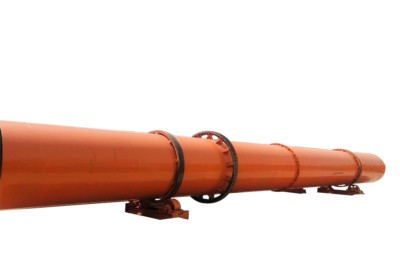

Cow dung dryer for sale (cow dung drying equipment, cow dung drying production line) is a special drying equipment specially used for drying chicken, cow, horse, duck and other livestock manure.

Composition Analysis of Cow Dung

Farmers know that directly drying cow dung as fertilizer for plants has a considerable effect and can effectively increase crop yields, but this still wastes the organic components in cow dung. Cow dung contains 14.5% organic matter, 0.30-0.45% nitrogen, 0.15-0.25% phosphorus, and 0.10-0.15% potassium. These components are used as soil fertilizers in planting industries. How to make reasonable use of cow dung dryers ( Cow dung drying equipment, cow dung drying production line) for processing, and then adding ingredients in the drying process, can greatly increase the value of cow dung.

Advantages and disadvantages of cow dung

Compared with other livestock manures, cow dung has relatively low organic matter, fine texture, high water content, slow decomposition, low calorific value, and is a slow-acting fertilizer, although the organic matter content of cow dung is less. However, there are many grass fibers, which are suitable for places where the soil is relatively sticky and needs to be improved. It can effectively increase the air permeability of the soil and supplement nutrients. It can be used for crops that require loose and fertile soil, and it is more suitable for foliage plants. suitable.

The use of dried cow manure

The main uses of cow dung dried by cow dung dryer (cow dung drying equipment, cow dung drying production line) are:

- The medium for planting edible fungus agarics bosporus;

- Using cow dung to ferment into nutritious Feed to raise earthworms;

- Sell as feed for breeding turtles, fish, snails, chickens, ducks, etc.;

- Used to make cow dung organic fertilizer, which can loosen the soil, improve the compaction of the land, and chelate trace elements in the land , Improve soil fertility, etc.;

- The dried cow dung can be used as clean energy to burn and generate electricity.

The dried cow dung has many other uses, and NPC machinery will not list them here.

Auxiliary equipment for cow dung drum dryer machine

Cow dung drier (cow dung drying equipment, cow dung drying production line) is mainly composed of hot air stove, conveying equipment, feeding device, crushing machine, drum dryer, transmission device, electrical system, discharging device, dust removal device and smoke exhaust system and other components. The heat source users can choose the one that suits them. Commonly used heat sources include: gas generator, direct heating stove, indirect stove, heat transfer oil, electric heating, steam, etc.

The working principle of cattle manure dryer

After the wet cow dung enters the dryer, the material is evenly dispersed in the dryer and fully contacted with the hot air under the stirring of the plate lifters evenly distributed in the drum, which speeds up the heat transfer and mass transfer of drying. During the drying process, the material is continuously dried under the action of the inclined lifting board and the hot air. The star discharge valve at the other end of the dryer discharges the finished product. The cow dung dryer can directly dry the manure with a water content of up to 70%-85% to about 12% of safe storage moisture at one time, which is convenient for the production of machine fertilizer. The whole drying process is carried out in a closed system, thereby reducing drying pollution of the environment during the process.

Performance characteristics of cow dung drying equipment

- Production process: This machine dries fresh cow dung with a moisture content of 65% through high-temperature drying, sterilization, decomposition and other processes to obtain pure cow dung organic fertilizer with a moisture content of less than 13%.

- Dried finished product: the organic fertilizer has a variety of nutrients necessary for crops. According to the test of the scientific research department, the nitrogen content of this fertilizer is 2.6%, the phosphorus content is 3.5%, the potassium content is 2.5%, the crude protein is 16-25%, and the organic matter is 45%. It is an ideal fertilizer for the cultivation of pollution-free green food, and it can also be used to feed fish, cattle, pigs, etc.

- Drum drying has a high degree of mechanization, large production capacity and continuous operation.

- The structure is excellent, simple, the material runs smoothly through the resistance of the cylinder, and the operation is convenient.

- Few failures, low maintenance costs, and low power consumption.

- Wide application range and good drying uniformity.

- It can also achieve the purpose of sterilization and deodorization while drying.

Technical parameters of cow dung fertilizer dryer

| Specifications(m) | Capacity(t/h) | Power(KW) | Reducer | Moisture Inputs(%) | Calorific value of fuel coal | Moisture Outputs(%) |

| HGJ¢1.2×12 | 1 | 5.5 | JZQ350 | 50±10 | ≥4000 | 10±5 |

| HGJ¢1.5×14 | 1.5-2 | 7.5 | JZQ350 | 50±10 | ≥4000 | 10±5 |

| HGJ1.8×16 | 2-3 | 15 | JZQ500 | 50±10 | ≥4000 | 10±5 |

| HGJ¢2.0×18 | 3-4 | 18.5 | JZQ500 | 50±10 | ≥4000 | 10±5 |

| HGJ¢2.2×18 | 4-5 | 22 | JZQ650 | 50±10 | ≥4000 | 10±5 |

| HGJ¢2.4×18 | 5-6 | 30 | JZQ650 | 50±10 | ≥4000 | 10±5 |

| HGJ¢2.6×18 | 8-10 | 30 | JZQ650 | 50±10 | ≥4000 | 10±5 |

| HGJ¢2.8×20 | 10-13 | 45 | JZQ750 | 50±10 | ≥4000 | 10±5 |

| HGJ¢3.0×22 | 13-16 | 45 | JZQ850 | 50±10 | ≥4000 | 10±5 |

| HGJ¢3.2×25 | 18-20 | 75 | JZQ850 | 50±10 | ≥4000 | 10±5 |

NPC Machinery Manufacturing Co., Ltd. pursues the principle of “credibility first, customer first”, and has always followed the quality policy of being responsible for each process, each product, and each user, and serves users wholeheartedly. It is necessary to check the technology and quality of the production equipment, and to carry out reasonable technical transformation on the equipment according to the specific needs of users, so as to meet the requirements of different users and meet the ideal use effect of users under different environmental conditions. In order to ensure that the equipment is always running in an ideal state, so that customers can use it with confidence and satisfaction, our company provides accessories and well-trained maintenance personnel to provide customers with fast, timely and excellent maintenance and emergency maintenance after-sales service.

When you choose us, you also choose the one stop service

The specific content of after-sales service is as follows:

(1) Assign special after-sales service personnel free of charge to arrive at the site to guide customers on installation and commissioning.

(2) On-site training of operators.

(3) Our company has its own wearing parts manufacturing plant, and cooperates with the factory to ensure timely supply of original spare parts.

(4) During the warranty period, we will be responsible for free replacement of all parts caused by quality or unnatural wear and tear.

(5) All repairs caused by natural wear and quality problems during the warranty period are free of man-hours.

Pre-sales: Be a good consultant and assistant to customers, so that every investment of users can get rich returns.

(1) Selection of equipment model.

(2) Design and manufacture products according to the special requirements of customers.

(3) Train technicians for customers.

(4) The company sends engineering and technical personnel to the user’s site for free to plan the site and design appropriate processes and programs for the user.

Sales: Respect customers; give customers peace of mind, ease, and surprise; commit to improving the overall value of customers.

(1) Acceptance of products.

(2) Assist customers to draw up construction plans.

After sales:

(1) Assign special after-sales service personnel free of charge to arrive at the site to guide customers on installation and commissioning.

(2) Equipment installation and commissioning.

(3) On-site training of operators.

(4) After the complete set of equipment is installed, 1-2 full-time technicians will be left to assist the customer in on-site production for free for one month until the customer is satisfied.