# Leading Technology Used in Organic Fertilizer Production Process

Organic fertilizer is a type of fertilizer that is derived from organic sources, such as animal manure, compost, green manure, or other biodegradable materials. Organic fertilizer can provide nutrients and organic matter to the soil, improve soil structure and fertility, enhance crop growth and quality, and reduce environmental pollution.

However, not all organic materials are suitable for direct application to the soil. Some organic materials may contain pathogens, weed seeds, heavy metals, or other contaminants that can pose risks to human health and the environment. Therefore, it is necessary to process the organic materials before using them as fertilizers.

There are various technologies for the production and application of organic fertilizers, depending on the type and quality of the raw materials, the desired form and composition of the final product, and the local conditions and requirements. In this blog post, we will introduce some of the leading technologies used in organic fertilizer production process, and their advantages and disadvantages.

## Thermal Drying

Thermal drying is a process that uses heat to reduce the moisture content of organic materials, such as animal manure or sewage sludge. Thermal drying can produce dry granules or pellets that are easy to store, transport, and apply. Thermal drying can also kill pathogens and weed seeds, and reduce odors and greenhouse gas emissions.

However, thermal drying also has some drawbacks. Thermal drying requires a lot of energy and can be costly. Thermal drying can also cause nutrient losses due to volatilization or oxidation, especially nitrogen. Thermal drying can also generate dust and air pollutants that need to be controlled.

## Composting

Composting is a process that uses microorganisms to decompose organic materials into humus-like substances. Composting can stabilize the organic materials, reduce their volume and weight, improve their nutrient content and availability, eliminate pathogens and weed seeds, and enhance their soil conditioning properties.

However, composting also has some challenges. Composting requires proper management of moisture, temperature, oxygen, carbon-to-nitrogen ratio, and turning frequency to ensure optimal decomposition. Composting can also produce odors and greenhouse gas emissions that need to be minimized.

## Vermicomposting

Vermicomposting is a process that uses earthworms to digest organic materials and produce worm castings. Vermicomposting can produce high-quality organic fertilizer that is rich in nutrients, enzymes, hormones, and beneficial microorganisms. Vermicomposting can also reduce pathogens and weed seeds, and suppress plant diseases.

However, vermicomposting also has some limitations. Vermicomposting requires suitable environmental conditions for earthworm survival and activity, such as temperature, moisture, pH, and salinity. Vermicomposting can also be affected by predators or pests that can harm the earthworms.

## Anaerobic Digestion

Anaerobic digestion is a process that uses anaerobic microorganisms to break down organic materials into biogas and digestate. Anaerobic digestion can produce renewable energy from biogas, which can be used for heating, electricity generation, or transportation. Anaerobic digestion can also produce nutrient-rich digestate that can be used as organic fertilizer or soil amendment.

However, anaerobic digestion also has some disadvantages. Anaerobic digestion requires high capital and operational costs for building and maintaining the digester system. Anaerobic digestion can also produce odors and greenhouse gas emissions that need to be controlled.

## Concentrated Organic Fertilizer Production

Concentrated organic fertilizer (COF) is a type of organic fertilizer that is produced by processing liquid manure with biologically active additives (BAA). COF can be produced in solid or liquid form, depending on the desired application method and dose. COF can provide high concentrations of nutrients to the crops, especially nitrogen.

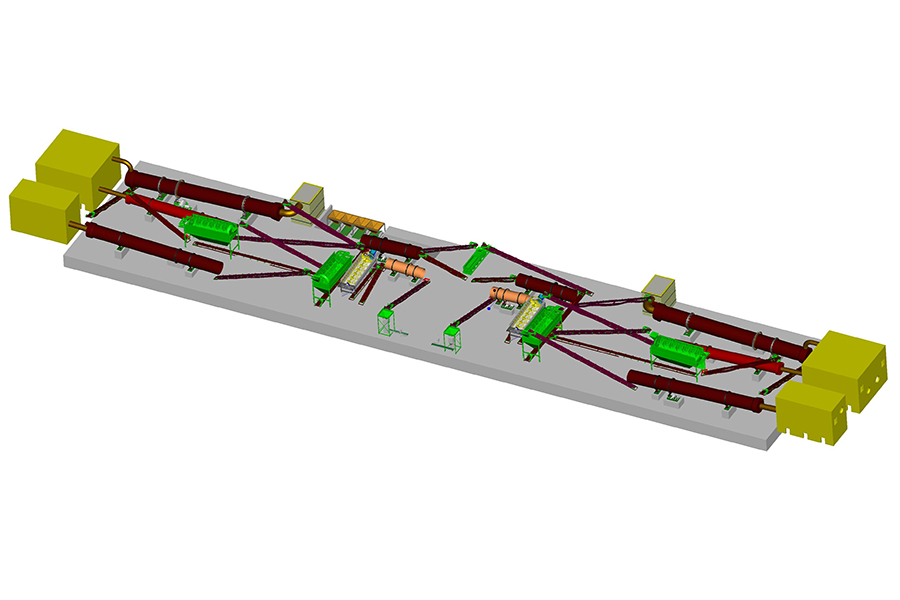

The technology for COF production involves a mobile unit for local processing of liquid manure with a capacity of up to 45 m3/h for initial manure; a tiller agitator with equipment for dosing the application of BAA with a capacity of up to 400 t/h; a machine for making solid COF with a pneumocentrifugal distributing body for their application on the surface with doses up to 4 t/ha; or a mobile unit based on machines for the application of liquid organic fertilizers (MALF) with autonomous equipment for mixing BAA with liquid manure and applying it in doses from 1 to 4 t/ha.

The advantages of COF production are that it can improve the soil biochemical parameters by increasing the organic matter content and microbial activity; it can increase the crop yield and quality by providing balanced nutrition; it can reduce the environmental impact by reducing the odor emission and nutrient leaching; it can save costs by reducing the transportation and storage of liquid manure.

The challenges of COF production are that it requires proper selection and dosage of BAA to ensure the optimal effect and safety; it requires careful monitoring and adjustment of the processing parameters to ensure the quality and stability of COF; it requires suitable equipment and machinery for the production and application of COF.

## Conclusion

Organic fertilizer production is a complex and dynamic process that involves various technologies and factors. The choice of the best technology depends on the specific situation and objectives of each producer and user. The main criteria for selecting the technology are the availability and quality of the raw materials, the desired form and composition of the final product, the economic and environmental benefits, and the local conditions and requirements.